SP-4206 Stages to Saturn

[57] At the time of Kennedy's historic pronouncement, the booster vehicle program was still in flux. The Saturn rocket was considered a multi-purpose vehicle, and the Department of Defense was still planning Earth-orbital missions using Dyna-Soar. During the summer and fall of 1960, NASA and Air Force executives were still engaged in mission studies using Dyna-Soar as a payload for Saturn.1 By January 1961, the DynaSoar appeared to have won an even stronger place in Saturn mission studies. In a planning session at Huntsville, the second stage of the Saturn C-2 configuration study was firmed up as to trajectory, performance, and structural considerations. All of these parameters derived from a Saturn and Dyna-Soar vehicle combination with the Dyna-Soar as the upper stage.2 Yet the C-2 configuration itself was only a paper study, and Saturn configurations changed rapidly in the early months of 1961.

At the opening of the new year, as NASA was still formulating its mission plans and goals, Glennan injected a note of caution into discussions involving a manned lunar landing because a formal announcement from the White House had not yet been made. In general, the mood at NASA was to proceed toward the lunar goal along a broad base of action, leaving open a variety of options including Department of Defense missions like Dyna-Soar. If all the options were pursued, then a broad series of booster vehicles needed to be developed, and von Braun was already hoisting storm signals about the allocation of manpower in NASA programs. At current levels, he noted, NASA would most certainly find itself overextended by trying to maintain parallel development of both the C-2 and the Nova.3

[58] During 1961, configurations seemed to change month by month. In January, the C-1 vehicle changed from a three-stage to a two-stage booster, eliminating the S-V upper stage to leave only S-I and S-IV stages; but S-V development continued during February. By May, the C-1 had become a possible three-stage vehicle again, including Block I and Block II interim versions. In February, the C-2 was ticketed as a three-stage vehicle for Earth-escape missions (featuring an S-II second stage); in May, there was talk of a need for an even more powerful vehicle for circumlunar missions; in June the C-2 was dropped in favor of a C-3, although Nova would continue; later in the year, there were plans for a C-4, along with a solid-booster C-1. By the end of the year, there was also the C-5.4 One result of this was the decline of Dyna-Soar, whose position as a NASA payload essentially evaporated after the C-2 cancellation in June.5

The rise and fall of vehicle configurations reflected the rapidly shifting concepts of mission profiles, payloads, schedules, and money. The fluctuating pattern of Saturn configurations and numbers created confusion even among those in government who were close to the program, as Hugh Dryden admitted in a letter to Hugh Odishaw, of the National Academy of Sciences. Written in March 1961, the letter also revealed the concern of some observers that future development of Saturn was a "dead end road." Such talk irritated Dryden. If critics were referring to the Saturn S-1 first stage, with a total thrust of 1.5 million pounds, then he admitted that maximum development was self-evident, since the propulsion came from the most advanced engines available from the ballistic missile program. Dryden complained that critics did not allow for advanced Saturns of much improved performance, using what he called "the Saturn engine."6 He could have been referring to either the F-1 or the liquid hydrogen propulsion system (known as the J-2), but both types of engine would be crucial for advanced configurations involving more ambitious missions. The C-3 version, for example, boasted two F-1 engines in the first stage (double the thrust of the existing Saturn C-1 first stage), four J-2 engines in the second stage, and a pair of J-2s in the third stage. During a high-level NASA conference in late July 1961, Milton Rosen emphasized that the United States was still in contention in the race for a manned lunar landing "only because we initiated J-2 and F-1 development at a relatively early date." If the United States intended to maintain a competitive position, Rosen warned, NASA had to capitalize on the use of these propulsion systems, both of which were still under development.7

Certainly if the F-1 and J-2 were to be the optimum engines, then the vehicle known as the Saturn C-5 promised to be an optimum booster. The designers at MSFC made a firm commitment to the C-5 by late 1961, [59] and NASA Headquarters gave formal approval for development on 25 January 1962. The C-5 was a three-stage vehicle, with five F-1 engines in the first stage, five J-2 liquid-hydrogen engines in the second stage, and one J-2 in the third stage. The C-5 could handle a number of missions, including 113 000-kilogram payloads into low Earth orbit, or 41 000 kilograms on a lunar mission, which could be a circumlunar voyage or a manned landing.8

During a spring meeting of various NASA managers at Langley Research Center, Hampton, Virginia, Ernst Geissler of MSFC reviewed the status of the booster program. Despite the welter of configuration changes and confusing nomenclature, one of the guiding principles of the vehicle development program continued to be the building block concept, an idea even more significant with the passage of time and realization of the immense costs and complexities of the program. "By qualifying individual components, such as stages, a fewer number of flights are necessary for high reliability of the total vehicle system," he emphasized. Moreover, the step-by-step approach allowed the space agency to experiment with various maneuvers in orbit, as required for different mission concepts.9 The Saturn C-1, at that time, was planned for vehicle development launches that would also include testing of the planned lunar spacecraft module in orbit and reentry, culminating in a series of manned flights. The spacecraft would thus be qualified in plenty of time, ready for launch aboard the C-5. Qualifying some of the C-5 hardware suggested possible problems, however, unless some preliminary flight tests occurred. Geissler referred to still a different launch vehicle, the C-IB. This interim vehicle, using the C-5's intended third stage as its own second stage, would take advantage of the proven C-1 first-stage booster. Thus, the C-1B would be able to qualify certain hardware and systems for the C-5, while demonstrating the feasibility of orbital operations inherent in C-5 mission concepts.10

Geissler summarized three principal modes for a lunar landing mission with the C-5 vehicle. Lunar orbit rendezvous (LOR) involved descent to the lunar surface from lunar orbit by using a small spacecraft that separated from a parent lunar satellite and then rejoined the orbiting spacecraft for the return home. Earth orbit rendezvous (EOR) involved the landing of a larger vehicle directly on the lunar surface, thus eliminating the descent and ascent of a separate spacecraft from orbit. But the EOR mode required rendezvous techniques in building up the necessary vehicle in Earth orbit. Geissler explained two different approaches. After launching two vehicles, the upper stages of each could be connected to form the lunar vehicle. An alternative was to transfer oxidizer from one vehicle to the other in Earth orbit. There was one more feasible way of going to the moon: if a large enough vehicle could be built, a single launch would suffice. MSFC refused to give up on Nova. The Nova in the spring of 1962 was to have 8-10 F-1 engines in the first stage, and a....

[60]

![Early design concepts of C-1 and C-5 versions of the Saturn launch vehicles.[link to a larger picture]](p60s.jpg)

....second stage mounting a powerful new LH2 engine, the M-1, under development by Aerojet General. Although Geissler predicted a test launch of the Nova by the autumn of 1967, the logic of development favored the C-5 because it was predicted to be fully operational by November 1967.11

Nova, like Dyna-Soar, seemed to evaporate as other issues were settled that placed a premium on the development of its nearest competitor, the C-5. On 11 July 1962, NASA officially endorsed the C-1B as a two-stage Saturn for Earth-orbital tests of Apollo hardware. At the same time, NASA confirmed the choice of the LOR mode for the lunar mission, thereby focusing development on the C-5. Early in 1963, NASA Headquarters announced a new nomenclature for its large launch vehicles. The C-1 became Saturn I, C-1B became Saturn IB, and C-5 became Saturn V. Nova was not even mentioned.12

The disarmingly simple NASA statement of 11 July 1962, confirming the choice of LOR as the mode, represented only the tip of a bureaucratic iceberg. The choice of LOR came after a series of skirmishes and....

[61]

![The stable of NASA launch vehicles that were actually built and flown. [link to a larger picture]](p61s.jpg)

....engagements among various NASA centers and within Headquarters. The struggle in reaching the final decision also suggested some of the problems to be faced by NASA management when one center had responsibility for the launch vehicle and another organization had the payload. The problems were compounded when both were trying to fashion programs and develop hardware without always knowing what each would require in the end.

The von Braun group, after all, had been developing both payload and boosters as integral systems for years. Now it would be necessary to defer to different design teams and accept outside judgments about payloads. In the case of Saturn, the payload development stemmed from the Space Task Group (STG) originally set up in October 1958 to manage Project Mercury. Located physically at Langley Research Center, Virginia, STG reported to the Goddard Space Flight Center at Greenbelt, Maryland. Beginning in 1959, STG received management responsibilities for studies leading to Project Apollo.13 In the spring of 1960, STG and MSFC began closer contact when STG organized a special liaison group, the "Advanced Vehicle Team," nine men headed by R.O. Piland and reporting directly to the STG chief, Robert R. Gilruth. Among other things, the Advanced Vehicle Team was to maintain appropriate contact with the various NASA centers, and, specifically, to maintain "the necessary liaison with the Marshall Space Flight Center in matters [62] pertaining to the development and planned use of boosters in the advanced manned space flight program."14

Early on, participants in the liaison effort discovered that their style did not always mesh with that of MSFC. One trip report from an STG team member in October 1960 noted von Braun's desire for additional meetings in November and December, and added, somewhat peevishly, "Dr. von Braun wants to participate. This probably means another ballroom meeting." Apparently the MSFC method was to have a large gathering for a semiformal presentation, then break into smaller groups for detailed discussions. "I've reached the opinion that MSFC staff have no qualms about playing one group against the other... if we have separate meetings," the correspondent complained, and warned STG to be careful.15

Perhaps part of the problem was STG's lesser standing vis-a-vis Marshall as a full-fledged center. This aspect was improved in January 1960, when STG became a separate field element, reporting directly to the NASA Director of Space Flight Programs, Abe Silverstein. As Director of STG, Gilruth had his own staff of some 600, still physically located at Langley. With a new organizational structure and bureaucratic independence, STG was authorized to conduct advanced planning studies for manned vehicle systems, as well as to establish basic design criteria. STG also had authority to assume technical management of its projects, including the monitoring of contractors. By November, STG became even more independent when it was officially redesignated the Manned Spacecraft Center (MSC),16 and plans were being made to transfer MSC to its new location near Houston, Texas, by the middle of 1962.

It is interesting that Gilruth and von Braun's emissary, Eberhard Rees, soon thereafter were stressing the "equality" of the two NASA centers. Meeting in July 1961, the two men also agreed on setting up four joint panels to cope with the growing problems of design, hardware, operational, and bureaucratic coordination: Program Planning Scheduling; Launch Operations; Apollo-Advanced Vehicles; Apollo-Saturn C-1. Each panel, in addition, included certain working groups for specific areas, with provisions for ad hoc joint study groups as the need arose. For problems involving other NASA agencies, there were special technical liaison teams. In general, technically knowledgeable members were assigned on a functional, rather than an organizational, basis; wherever possible, the responsibilities of experienced personnel already assigned to internal working groups were increased.17

Naturally, all concerned hoped that the joint groups would promote understanding and reduce friction. That the Apollo-Saturn program succeeded as well as it did testifies to the value of such efforts, but this is [63] not to say that differences of opinion were always easily and quickly adjusted. The issue of EOR versus LOR, for example, brought Marshall and the Manned Spacecraft Center into head-on conflict.

Early in 1961, NASA's studies for a manned lunar landing were keyed to the EOR mode using a Saturn vehicle or to direct ascent with the Nova.18 In view of MSC's later acceptance of LOR, Gilruth's initial support of the direct ascent concept is intriguing. "I feel that it is highly desirable to develop a launch vehicle with sufficient performance and reliability to carry out the lunar landing mission using the direct approach," he wrote to NASA Headquarters reliability expert Nicholas Golovin in the autumn of 1961. As for the rendezvous schemes (and here he apparently referred only to EOR), Gilruth said that they compromised mission reliability and flight safety, and that they were a "crutch to achieve early planned dates for launch vehicle availability, and to avoid the difficulty of developing a reliable Nova Class launch vehicle." At the same time, he understood the need for an Earth parking orbit during any mission to allow adequate time for final checkout of spacecraft, equipment, and crew readiness before going far from Earth.19

The concept of lunar orbital rendezvous (LOR) had been studied at Langley Research Center as early as 1960. The idea was passionately advocated by John Houbolt, a Langley engineer who first encountered it while investigating rendezvous techniques for orbiting space stations. The Langley-Houbolt concept of LOR was soon absorbed by the STG-MSC crew, and MSC eventually became the leading champion of LOR.20 Houbolt played a key role in converting Headquarters planners to the LOR concept. Convinced that the idea had not received a fair hearing, Houbolt bypassed everyone and wrote directly to Associate Administrator Robert C. Seamans, Jr., in November. Fulminating at what he viewed as grandiose plans for using boosters that were too large and lunar landers that were too complex, Houbolt urged consideration of LOR as a simple, cost-effective scheme with high likelihood of success. "Give us the go-ahead, and a C-3," Houbolt pleaded, "and we will put man on the moon in very short order."21

Houbolt's letter apparently swayed several managers at Headquarters, especially George Low, Director of Space Craft and Flight Missions, in the Office of Manned Space Flight (OMSF). But D. Brainerd Holmes, who presided over OMSF, still had a prickly managerial problem. There remained people at Headquarters with doubts about LOR, principally Milton Rosen, newly named Director of Launch Vehicles and Propulsion in OMSF. Early in November, Holmes and Seamans directed Rosen to prepare a summary report on the large launch vehicle program, which of necessity dealt with the issue of EOR-LOR-direct ascent. The Rosen study came on top of several other committee reports on vehicles and....

[64]

|

.

|

|

|

. |

|

|

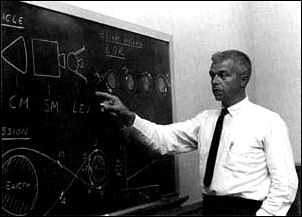

![the typical mission profile using lunar orbit rendezvous. [link to a larger picture]](p64s.jpg) | ||

[65] ...landing modes, Rosen's group of 11 people, including 3 from MSFC (Willy Mrazek, Hans Maus, and James Bramlet), submitted its report on 20 November.22

The issue of how to achieve a lunar landing at the earliest date became a principal theme in the Rosen group's deliberations. Although rendezvous offered an early possibility of a manned lunar landing, Rosen's working group noted that actual rendezvous and docking experience would not be available until 1964. LOR also seemed the riskiest and most tricky of the rendezvous modes, and the group expressed a decided preference for EOR. Either way, a C-5 Saturn with five F-1 engines in the first stage was the recommended vehicle. In spite of all the discussion of rendezvous, the Rosen committee in the end favored direct ascent as opposed to either EOR or LOR. "The United States should place primary emphasis on the direct flight mode for achieving the first manned lunar landing," the report flatly stated. "This mode gives greater assurance of accomplishment during this decade." Therefore, the Nova vehicle "should be developed on a top priority basis."23 The trend toward LOR strengthened, however. Even though EOR became the "working mode" for budgetary planning for 1962, the debate went on.

Holmes hired Joseph Shea, an energetic young engineer, as Chief of the Office of Systems Engineering in OMSF, with responsibilities to conduct and coordinate mission mode studies. Holmes also instituted a top-level series of meetings under the rubric of "The Management Council," to discuss issues involving Headquarters and more than just one center alone.24 At just about every meeting of the Management Council, Rosen and Gilruth got into a debate over the mode choice. Finally, as Rosen recalled, Gilruth came up to him after one of the meetings had adjourned and made one more pitch for the LOR mode. The most dangerous phase of the mission, Gilruth argued, was the actual landing on the moon. If Rosen's direct ascent idea was followed, then at the moment for lunar descent, that meant landing an unwieldy vehicle that was both quite long and quite heavy. A very touchy operation, Gilruth emphasized. LOR, on the other hand, boasted an important advantage: the lunar landing and lunar takeoff would be accomplished by a very light and maneuverable vehicle specifically designed for the task. Rosen confessed he had been preoccupied with simplicity from one end of the mission-the launch from Earth-and he had no convincing counterarguments when Gilruth made him look at simplicity from the other end, the lunar landing.25

While the consensus at Headquarters now shifted towards LOR, the split between MSC and MSFC showed few signs of easing. On a swing through both MSC at Langley and MSFC at Huntsville in January 1962, Shea was discouraged by the entrenched position of the two centers: Marshall people displayed an "instinctive reaction" of negativism on the [66] issue of LOR, while MSC personnel seemed too enthusiastic, even unrealistic, about rendezvous problems and the weight situation. Each center, Shea observed, intent on its own in-house studies, "completely ignores the capability of the other's hardware."26 During the spring, however, MSC's research seemed to become more convincing. MSFC also began to regard LOR with increased interest. In mid-April, an MSC presentation at Huntsville elicited several favorable comments from von Braun himself.27

The evidence suggests that von Braun increasingly felt the necessity of settling the issue so that they could get on with definitive contracts for launch vehicles and other hardware with long lead times.28 Resolution of the EOR-LOR controversy finally came on 7 June 1962, when Shea and his aides were in Huntsville for still another session on the mode of rendezvous. In his concluding remarks, von Braun noted that the conference had given six hours of intensive analysis to various proposals, including Nova-direct as well as EOR and LOR. They all appeared to be feasible, von Braun commented; the problem was narrowing the choices to one and then acting on it. "It is absolutely mandatory that we arrive at a definite mode decision within the next few weeks, preferably by the first of July 1962," he declared. "We are already losing time in our overall program as a result of lacking a mode decision." Then von Braun announced that LOR was Marshall's first choice.

There were complex technological, economic, and administrative reasons for Marshall's ultimate decision to go along with LOR. Although von Braun elaborated on 11 principal reasons for choosing LOR, the basic consideration involved confidence that it provided the best chance for a successful manned lunar landing within the decade. The concept promised good performance margins. Separation of the lunar lander from the reentry vehicle seemed desirable from many considerations of design and operation, and the overall concept suggested good growth potential for both the lander and the booster. Von Braun also implied that both sides could work together without the potential friction of an "I told you so" attitude. The fact that he felt compelled to proffer such a verbal olive branch suggests that the heat generated by the EOR-LOR debate must have been considerable. The MSFC Director observed that "the issue of 'invented here' versus 'invented there' does not apply," because both MSC and MSFC, in effect, adopted an approach originally put forth by Langley. "I consider it fortunate indeed for the Manned Lunar Landing Program that both Centers, after much soul searching, have come to identical conclusions," von Braun emphasized. "This should give the Office of Manned Space Flight some additional assurance that our recommendations should not be too far from the truth."

Quickly ticking off the reasons for deciding against EOR, von Braun pointed out that it was still feasible. A looming negative factor was the double loss incurred if, for example, the tanker launch went just fine, but [67] the manned launch was postponed too long on the pad or had to abort during ascent, wiping out the mission to the cost of two complete launch vehicles and associated launch expenses. In addition, von Braun noted complex management and interface problems with dual launches. Using the C-5 in a direct launch posed some thorny technical problems and permitted only the thinnest margins in weight allowances for the spacecraft, so the C-5 direct route was rejected. The huge Nova booster could have solved some of these problems, but it was rejected principally because of its size, which would have created requirements beyond the existing scope of fabrication and test facilities available to NASA; there were also serious problems seen in time, funding, and technical demands for a booster of Nova's dimensions.29

Even with von Braun's imprimatur in June, the irrevocable decision for LOR did not come until the end of 1962. The Huntsville conclave produced agreement at the center level only; NASA Headquarters still had to formalize the choice and implement the decision. Early in July, Seamans, Dryden, Webb, and Holmes concurred with a recommendation for LOR by the Manned Space Flight Management Council, but the President's Scientific Advisory Committee still actively questioned the LOR mode. The committee evidently preferred the EOR approach because it felt the technological development inherent in the EOR concept had more promise in the long run for civil and military operations; its argument also suggested that the LOR choice stemmed from internal NASA expediency-as the cheapest and earliest mission possibility-even though technical analysis of LOR was incomplete. Nicholas Golovin and Jerome Wiesner, in particular, remained adamantly against LOR, and the controversy actually boiled over into a public exchange between Wiesner and NASA officials at Huntsville while President Kennedy was touring Marshall Space Flight Center in September.

Host von Braun and the President were standing in front of a chart showing the LOR maneuver sequence. As von Braun proceeded to explain the details, Kennedy interrupted, "I understand Dr. Wiesner doesn't agree with this," and turned around to search the entourage of newsmen and VIPs around them, "Where is Jerry?" Kennedy demanded, Wiesner came up to join Kennedy and von Braun, with Webb, Seamans, and Holmes also in the group. Wiesner proceeded to outline his objections to LOR, and some lively dialogue ensued, just out of the earshot of straining newsmen and dozens of onlookers on the other side of a roped-off aisle. "They obviously knew we were discussing something other than golf scores," Seamans recalled. In fairness to Wiesner, Seamans later noted, the President's scientific advisor had to play the devil's advocate on many issues when a robust agency was vigorously pressing its position. Wiesner's job was to make sure that the President received alternative views, and he once confided to Seamans that he was....

[68]

.....not always comfortable in having to take negative points of view as Kennedy's advisor. Certainly, the LOR issue was one such example. As Seamans phrased it, "Here the President had his advisors recommending one approach and the line operators recommending another." It was also one notable instance when Kennedy took a tack opposed to the PSAC position and supported NASA's decision for the LOR mode.30

After a final round of studies, James Webb reaffirmed full commitment to LOR on 7 November and named a prime contractor, Grumman Aircraft Engineering Corporation, to build the lunar module.31 Thus, by the end of 1962, the outlines of the Apollo-Saturn program were firmly delineated, with agreement on a family of three evolutionary Saturn vehicles, a functionally designed spacecraft, a technique to land men on the lunar surface, and a technique to return them safely to Earth.

The Saturn program created a vast new aerospace enterprise, partly private and partly public, with MSFC directing a group of facilities whose extent far exceeded anything in the days of the old NACA. The federally owned facilities under Marshall's immediate jurisdiction eventually included the sprawling installation at Huntsville; the cavernous Michoud Assembly Facility (MAF) at New Orleans; the huge Mississippi Test Facility (MTF) at Bay St. Louis, Mississippi; and the Slidell Computer Facility at Slidell, Louisiana. Other government-owned facilities directly related to the Saturn program included the NASA Rocket Engine Test Site at Edwards [69] Air Force Base in California and the government-owned production facilities for the S-II second stage at Seal Beach, California.

The growth of Marshall Space Flight Center at Huntsville began almost as soon as the transfer of the von Braun team from the Army Ballistic Missile Agency in 1960. This shift involved some 4.8 square kilometers of land (within the 162 square kilometers of the Redstone Arsenal) and facilities valued at $96 000 000, along with 4670 employees from ABMA's Development Operations Division. (For subsequent figures on manpower, plant value, etc., see the appendixes.) Settling in its new role, MSFC evolved as a facility of three distinct sectors, divided into an administrative and planning area, an industrial area, and test area. Although the transfer gave NASA the bulk of the land and facilities previously used by ABMA's Development Operations Division, von Braun's administrative staff was allowed to remain in their old ABMA offices on a temporary basis only, and a Saturn-sized test area was needed. Construction began on a new administrative complex and the first MSFC personnel took occupancy during the spring of 1963. Of the several approaches to the center, perhaps the most impressive was from the north. Driving several miles through the green pastures and wooded, rolling hills of the Alabama countryside, a viewer watched the administrative complex looming ever larger. Three multistory buildings were arranged in a "V" shape, with Building 4200, the tallest of the three, proudly riding the crest of a low hill. With the U.S. flag snapping smartly from its pole, this impressive office complex rising out of the rural landscape rarely failed to impress visitors. As director of the Marshall Space Flight Center, von Braun, with his staff, occupied office suites on the top two floors of Building 4200, irreverently known as the "von Braun Hilton."

Once over the crest of the hill, the visitor saw the rest of the Marshall complex stretching for several miles to the Tennessee River. In the foreground, the former ABMA laboratories and manufacturing areas occupied the equivalent of many city blocks. The labs incorporated facilities for a host of esoteric research projects, computation, astrionics, test, and other specialized research activities. Buildings for manufacturing, engineering, quality and reliability assurance, and others had cavernous, high bay areas attached to accommodate the outsized Saturn components. In the background, the skyline was punctuated by the silhouettes of the assorted test stands and other installations of the expanded test area. Here were the engine test stands, an F-1 engine turbopump test position, and two especially large installations visible for miles. One was the big, burly test stand for the S-IC first stage, 123 meters high, completed in 1964. The second was the Dynamic Test Stand, 129 meters high, designed to accommodate the complete Saturn "stack" of all three booster stages, the instrument unit, and the Apollo spacecraft. Inside the Dynamic Test Stand, heavy duty equipment shook [70] and pounded the vehicle to determine its bending and vibration characteristics during flight. Still further to the south, specially built roads for transporting the bulky Saturn flight stages led to docking facilities on the Tennessee River, where barges picked up or dropped off stages en route to other test sites or launch facilities at Cape Kennedy.32

Except for the lawns and plantings around the administrative complex, Huntsville always had a factory look about it. Crisscrossed by streets and railroad tracks, Marshall still bore the stamp of its heritage as an Army arsenal, with lean, utilitarian structures, linked together by a web of electric and phone lines supported by ubiquitous poles. Buildings in the industrial area were frequently flanked by ranks of high-pressure gas bottles, cranes, hoists, and assorted large rocket components. A visit to the Manned Spacecraft Center at Houston, with its sleek, ultramodern office complexes and well-tailored inner courtyards (complete with ponds and rocky little streams) was a study in contrasts.

When Marshall was organized in 1960, the Army launch team under the direction of Kurt Debus became the Launch Operations Directorate, Marshall Space Flight Center. At the Army's Missile Firing Laboratory, the Debus team had been launching a series of Army vehicles, including Redstone and Jupiter, and had launched the first American Earth satellite, Explorer I. In the months following the transfer to NASA, they launched the manned Mercury-Redstone suborbital flights. As plans for the Saturn series were finalized, the Launch Operation Directorate, through Debus, participated in the search for a new launch site, large enough and removed far enough from population centers to satisfy the physical requirements of the big new space boosters. Cape Canaveral was chosen, and development of the new facilities began, with Launch Complex 34 becoming operational during the fall of 1961 to launch the first Saturn I vehicles.

The immense task of constructing new launch pads and developing the huge installations required for Saturn V operations called for a separate administrative entity. In March 1962, NASA announced plans to establish a new Launch Operations Center (LOC) at the Cape, and the change became effective on 1 July 1962. While close liaison continued, launch operations ceased to be a prime responsibility of MSFC, and Kurt Debus proceeded as Director, LOC, to develop the launch facilities for the Apollo-Saturn program.33

Large as it was, the aerospace complex at MSFC could not begin to accommodate the escalating dimensions of the Saturn program. Consistent with its heritage as an Army arsenal with an extensive in-house capability, Marshall manufactured the first eight models of Saturn I's first stage and did the testing in its backyard. The physical size of other Saturn stages, the frequency of testing as production models came on line, and the sheer magnitude of the endeavor dictated the need for additional facilities located elsewhere. Each major contractor developed the....

[71]

....special industrial capabilities required for the unique sizes inherent in the Saturn program, including fabrication, manufacturing, and testing. There was a certain kaleidoscopic aura about all these arrangements, since some were accomplished entirely by the contractor on privately owned premises and others were undertaken in government-owned facilities, with the contractor supplying most of the work force.

For example, the Saturn IB and Saturn V first stages were manufactured at the Michoud Assembly Facility (known familiarly as "Michoud") 24 kilometers east of downtown New Orleans. The prime contractors, Chrysler and Boeing, respectively, jointly occupied Michoud's 186 000 square meters of manufacturing floor space and 68 000 square meters of office space. The basic manufacturing building, one of the largest in the country, boasted 43 acres under one roof. By 1964, NASA added a separate engineering and office building, vertical assembly [72] building, (for the S-IC) and test stage building (also for the S-IC). By 1966, other changes to the site included enlarged barge facilities and other miscellaneous support buildings. Two things remained unchanged: a pair of chimneys in front of the Administration Building, remnants of an old sugar plantation. These ungainly artifacts served as reminders of Michoud's checkered past, from a plantation grant by the King of France in 1763, to ownership by the wealthy but eccentric New Orleans recluse and junk dealer, Antoine Michoud. Never a successful plantation, its sometime production of lumber and other local resources from the swampy environs helped generate the local slogan, "from muskrats to moonships."

The plant itself dated back to World War II, when it was built to produce Liberty ships. A hiatus in contract agreements shifted the emphasis to cargo planes, but only two C-46 transports rolled out before the war ended. The government facility remained essentially inactive until the Korean War, when the Chrysler Corporation employed over 2000 workers to build engines for Army tanks. Dormant since 1954, the building had been costing the government $140 000 per year to keep up. With so many jobs in the offing and the obvious level of economic activity to be generated by the manufacture of large rocket boosters, selection of the site occurred in a highly charged political atmosphere, with active lobbying by a number of congressmen and chambers of commerce from around the country. Eventual selection of the Michoud facility in 1961 followed a series of thorough NASA investigations, and Michoud easily fulfilled several high-priority considerations: production space and availability; location near a major metropolitan area; convenient year-round water transport facilities (to haul the oversized Saturn stages); and reasonable proximity to MSFC, the Cape, and a contemplated test-firing site for the finished stages.34

The extent of computer services required for the activities at the Mississippi Test Facility and Michoud prompted MSFC managers to consider a major computer installation to serve both operations. Happily, a location was found that included a structure originally designed to support sophisticated electronic operations. At Slidell, Louisiana, 32 kilometers northeast of Michoud and 24 kilometers southwest of MTF, Marshall acquired a modern facility originally built by the Federal Aviation Administration. For modifications and installation of new equipment, MSFC spent over $2 000 000 after acquiring the site in the summer of 1962. The array of digital and analog computers for test, checkout, simulation, and engineering studies made it one of the largest computer installations in the country.35

In contrast to Michoud, where the plant facility sat waiting, the development of the Mississippi Test Facility became a contest with Mississippi mud-to say nothing of the poisonous snakes and clouds of mosquitoes that plagued construction workers. Although NASA began [73] with a list of 34 potential locations, the site for test-firing Saturn V rocket stages logically had to be close to the production facilities at Michoud and also be accessible by water for shipment of S-II stages. Other criteria quickly ruled out most of the other contending sites. The test area had to be big. Size was a safety factor; test sites had to be widely separated from critical support and supply facilities in case of accidental destruction of a stage during a test run. More important, at the time the test facility location was being debated, NASA designers were looking ahead to big, deep-space booster stages of up to 111 million newtons (25 million pounds) of thrust, and lots of noise. Therefore, a test area of expansive proportions was required but in a location where a minimum number of people would have to be relocated. After juggling all of these requirements, in October 1961 NASA settled on a sparsely populated corner of Hancock County, Mississippi. A new, $300-million-plus space-age facility was hacked out of soggy cypress groves, Devil's Swamp, Dead Tiger Creek, and the Pearl River. By the intracoastal waterway and the Pearl River, MTF was only a 72-kilometer barge trip from the production facilities at Michoud, and was accessible by water to MSFC and the Cape.

The central test area, around the test stands, comprised 55 square kilometers, with a buffer zone of 518 square kilometers surrounding it. Approximately 850 families from five small hamlets were resettled outside MTF boundaries. The central test area was exclusively reserved for NASA use, and although the buffer zone was uninhabited, the area continued to be lumbered and teemed with wildlife, including wild hogs descended from abandoned farm stock. An employee picnic in 1967 frugally consigned some of these natural resources to a barbecue pit.36

At the heart of MTF were the monolithic test stands: a dual-position structure for running the S-IC stage at full throttle, and two separate stands for the S-II stage. Laboratories, monitoring equipment, control center, and storage areas, including docks, were all deployed thousands of meters away. The MTF complex was tied together by 12 kilometers of canals (with navigation locks and a bascule bridge); 45 kilometers of railroads; and 56 kilometers of roads and paved highways. Under it all snaked 966 kilometers of cables, connecting test stands, laboratories, and data banks. Each month, MTF consumed enough electricity to keep 6000 households functioning.

An arm of MSFC at Huntsville, MTF had an administrative pattern that was a bit unusual. A comparatively small cadre of NASA personnel (about 100) carried out overall managerial and supervisory duties. This select group also made the final evaluation of test results and issued the flight-worthiness certificates to the stage contractors. Approximately 3000 contractor personnel made up the vast majority of the work force. North American and Boeing each had several hundred people running their respective test stands. The General Electric Company, with over 1500 people, had the contract for housekeeping services at MTF and [74] provided maintenance for the facility and operational support at the test stands and elsewhere for the other tenants, including the construction firms. GE's range of support ran the gamut from 19 special items of cable equipment (for $ 1 183 187), to the always popular snake bite kits ($1.25 each). On occasion, GE hired cowboys to round up stray cattle in the outreaches of MTF, and it was GE that arranged for the transfer of the cemeteries during resettlement of the area's small towns.

Development of MTF had a hectic air about it. Construction delays mounted by early 1964, after Mississippi went through a highly unusual cold snap and a snowstorm. Heavy rains came during January, topping records that had been on the books for 30 years. The schedules for construction and testing merged to the point where the first test firings in 1966 were being planned concurrently with ongoing construction. The MTF director, Jack Balch, observed: "We're sure this is the only way to do it, but for the next year we'll be riding with one foot on each of two galloping horses." The government-industry team at MTF did the job; the first stage-firing test, a 15-second test of the S-II stage, was performed successfully on 23 April 1966 in the test stand designated A-2. On 3 March 1967, a 15-second test of the S-IC-T (test) stage activated the first-stage facility. In September 1967, the other S-II stand, designated A-1, was declared operational.37

While these facilities were being developed, MSFC drew on experience, accumulated during the days of ABMA and the Army's arsenal concept, and developed the Saturn I-the vehicle originally designated as Juno V. On the threshold of starting to work on the large Juno V class of vehicles and other space hardware in 1959, Dr. Ernst Stuhlinger, von Braun's chief scientific advisor at ABMA, briefed NASA officials on the range of expected challenges and research required to develop vehicle components for space exploration. He noted the potential hazards from radiation, meteors, temperature extremes, and weightlessness. To cope with these environments, Stuhlinger stressed the need for research on a broad front, including special investigation into a list of 11 crucial materials and their current shortcomings in the space environment- from the decomposition of dielectrics and sealants, to unusual regimes of friction and wear for bearings and various moving parts, to the degradation of plastic and exposed surfaces, and to the vaporization and vacuum sticking of metals.38 Specific investigation of these and other problems moved on parallel tracks with the integration of components and materials into the launch vehicle design, even while the launch vehicle itself was taking form on drawing boards and in machine shops.

[75]

[76] Like most major development projects, the evolution of the Saturn I changed between conception and execution, although the configuration that emerged in 1958 was subjected to remarkably few major design variations before its first launch in 1961. The basic outlines for ABMA's concepts of the Saturn I (when it was still called Juno V) were sketched out in two reports to Advanced Research Projects Agency (ARPA) in October and November 1958; insights on various aspects of early design choices were provided by von Braun himself in ABMA's presentation to NASA in December 1958. For example, original concepts for yaw, pitch, and roll control called for hinged outer engines: two hinged for pitch; two hinged for yaw; all four for roll. But application of adequate control forces required fairly high deflection of the engine thrust vector, and the engine contractor (Rocketdyne) complained that this would put too much stress on propellant flex lines. Instead, gimbaling of all four outer engines was adopted, achieving adequate control force with less engine deflection. The gimbal system for mounting engines permitted each engine in the cluster to swivel about for either yaw or pitch control.

On the other hand, the original multiengine concept was maintained. Throughout the early design phase, ABMA stressed the reliability of the multiengine approach in case one or even two were lost. Particularly in the case of manned missions, von Braun emphasized, the engine-out capability offered much higher margins of safety in continuing a mission until conditions were less hazardous for separation of the crew capsule.

The multitank design also persisted as a design choice. In his NASA presentation, von Braun praised the multitank design for several reasons. Component tanks could be flown by Douglas C-124 Globemasters to any part of the world and reassembled for launch; this procedure would provide a high degree of flexibility. The separate tanks eliminated the technical difficulties of internal horizontal bulkheads, required in a large tank vehicle, to keep fuel and oxidizer separate. It also meant a shorter, and more desirable, vehicle. In spite of the added weight, most rocket propellant tanks included internal fuel slosh baffles, because splashing and surging of the liquid fuel created problems in keeping the vehicle stable and under control. In 1958, von Braun predicted that no fuel slosh baffles would be required in the multitank design because of the small diameter of the individual tanks (although the flight versions actually incorporated slosh baffles in their design). A great deal of attention was also given to booster recovery schemes, in which the spent first stage would be recovered from the ocean after its descent had been slowed by retrorockets and parachutes. The Huntsville group foresaw immense savings in the recovery scheme, since the illustration given by von Braun assumed "5 or 19 years from now" a launch rate of 100 vehicles per year over a 5-year period, at a cost of about $10 million per launch.39

[77] More than any of the Saturn vehicles, the Saturn I S-I stage configuration evolved during flight tests (for details, see chapter 11). NASA developed the Saturn I as first-generation and second-generation rockets, designated Block I and Block II. The first four launches used the Block I vehicle, with inert upper stages and no fins on the first stage, the S-I. Block II versions carried a live second stage, the S-IV, sported a corolla of aerodynamic fins at the base, and used uprated H-I engines. The S-I first stage for the Saturn I also became the first stage of the Saturn IB; in this application, it was called the S-IB. Again, there were modifications to the fins, engines, and various internal components. Nevertheless, the basic details of fabrication and testing of the Saturn I and Saturn IB remained similar. The first stage of the Saturn I and IB may have looked like a plumber's nightmare, but it fit the criteria of conservative design and economy established early in the program. As Marshall engineers discovered, development of a new booster of Saturn I's size involved a number of design problems. Fabrication of the tankage was comparatively easy. Even though the former Redstone and Jupiter tanks had to be lengthened from 12 to 16 meters to carry added propellants, the basic diameters of the 178-centimeter Redstone and 267-centimeter Jupiter tanks were retained, so they could be fabricated from the tooling and welding equipment still available at Huntsville. The tank arrangement settled on by MSFC gave an alternate pattern of the four fuel and four oxidizer tanks, clustered around the 267-centimeter center oxidizer tank. The oxidizer tanks carried the load from the upper stages of the Saturn, the fuel tanks only contributing to the lateral stiffness of the cluster. When filled, the oxidizer tanks contracted 63.5 millimeters, which meant that the fuel tanks had to have slip joints at their upper ends to accommodate other structural elements that fluctuated with the tank shrinkage. All together, the Saturn I first stage carried 340 000 kilograms of propellants in its nine tanks. To keep the propellant in one tank from depleting too rapidly during flight, which would seriously unbalance the vehicle, the Saturn I incorporated an interconnecting pipe system, with regulating equipment to keep propellants at uniform level in all tanks during a mission. Each of the four outboard fuel tanks fed two engines, yet interconnected with the other tanks. The 267-centimeter center liquid-oxygen (LOX) tank provided series flow to the four outboard LOX tanks, which also fed two engines apiece.

Although the group of tanks eased the potential slosh tendencies of a single large tank, each separate cylinder contained fixed baffles, running accordionlike down the tank interiors. Pressurization for the LOX tanks was done by a heat exchanger, dumping it into the top of the LOX tanks as gaseous oxygen. Gaseous nitrogen from fiberglass spheres at the top of the booster pressurized the fuel tanks. The 48 spheres fixed to the top of the stage were curiously reminiscent of bunches of grapes.

The cluster of tanks was held together at the base by the tail section [78] and at the top by an aptly named structural component known as the "spider beam." The tail section consisted of the thrust structure assembly as well as the heat shield, shrouding for engine components, holddown points, stabilizing fins (on the later Saturn I first stages), and other components.

Assembly of the spider beam required a special fixture for precise alignment and joining of the heavy aluminum l beams, of which it was made. Starting with a hub assembly, eight radial beams were attached to it at 45-degree intervals. Then eight more cross beams were joined to the outer ends of the radials with splice plates. The spider beam played a dual role. Special hardware attached to it was used during the initial clustering of the tanks. In other words, the spider beam served as an assembly fixture, then remained as part of the stage's permanent structural assemblies, with each outboard oxidizer tank affixed to the beam. Because a smaller diameter upper stage of 5.6 meters was planned for the Saturn I, an upper shroud was incorporated as part of the structural transition from the larger 6.5-meter-diameter first stage. The upper shroud also enclosed telemetry equipment, umbilical connection points used in ground test and launch preparation, and space for the recovery system for the first stage. In the later versions (the Block II models), the shroud section was eliminated, and instruments were housed in a separate instrument segment atop the upper stage. The recovery section was no longer required; additional studies, completed by early 1962, indicated that the recovery scheme would require extensive modification to the stage, so the idea was finally dropped.40

In the process of refining the design of the Saturn I, two major problems emerged: stability and base heating. As with most large rockets, the Saturn I was highly unstable, with the overall center of gravity located on the heavy, lower-stage booster, while the center of lift, in most flight conditions, was high on the upper stages. The nature of the problem called for more advanced control processes than used on aircraft and rockets the size of ICBMs. The low natural frequency of the big vehicle was such that when the gimbaled engines moved to correct rocket motions, special care had to be taken not to amplify the motions because the control system frequency was close to that of the vehicle itself.

More worrisome, at least in the early design stage, was the problem of base heating. Even with a rocket powered by only one engine, the flow pattern at its base proved nearly impossible to predict for the various combinations of speed and altitude. Base heating occurred when the rocket exhaust interacted with the shock waves trailing behind the vehicle. This clash created unpredictable regions of dead air and zones of turbulent mixing. Heated by the rocket exhaust, the air trapped in these areas in turn raised the heat levels at the base of the rocket to undesirable temperatures. Worse, the fuel-rich exhaust flow from the engine turbopump could get caught in these "hot-spot" regions, causing fire or explosion.

[79] The base heating phenomenon became worse with multiengine rockets. The eight-engine Saturn I cluster began to look like a Pandora's box of base heating. To get an idea of what to expect, and to work out some fixes ahead of time, the Saturn design team ran some cold flow tests, using scale-model hardware, and called on NASA's Lewis Research Center, in Cleveland, to run some unusual wind tunnel tests. These investigations involved a booster model with eight operating engines, each putting out 1100 newtons (250 pounds) of thrust. Following the tests and extensive theoretical studies, designers in Huntsville came up with several ideas to cope with the base-heating situation. Arranged in a cross-shaped configuration, the engine pattern of the cluster was conceived to minimize dead air regions and turbulent zones. The four inner engines were bunched together in the center to reduce excessive heating in the central area, and the remaining four were positioned to avoid structural interference as the gimbaled engines swung on their mounts. The lower skirt was designed to direct large streams of high-energy air toward the four center engines in particular to prevent dead air regions from developing in their vicinity. A heavy fire wall was installed across the base of the booster near the throat of the engines, with flexible engine skirts to permit gimbaling and, at the same time, keep the super-heated gas from flowing back up to the turbopumps and propellant lines above. The problem of the exhaust from the turbopumps received special attention. For the four center engines, which were fixed, the fuel-rich exhaust gases were piped to the edge of the booster skirt and dumped overboard into a region of high-velocity air flow. In later vehicles, the exhaust gases were dumped exactly into the "centerstar" created by the four fixed engines. The gimbaled outboard engines required a different approach. The turbopump was fixed to the gimbaled engines; therefore an overboard duct for them would have required a flexible coupling that could withstand the high temperatures of the turbine exhaust gases. Instead, MSFC devised outboard engine attachments called aspirators, which forced the turbine exhaust into hoods around the engine exhaust area and mixed the turbopump exhaust with the engine's main exhaust flow.41

Successful ignition and operation of an eight-engine cluster of Saturn's dimensions required extensive testing beforehand. In December 1958, ARPA released funds for modifications to one side of a two-position Juno test tower in order to test-fire the Saturn I first stage. Preparations for these static tests, as they were called, required extensive reworking of the Saturn's side of the tower, including a new steel and concrete foundation down to bedrock, a steel overhead support structure and a 110-metric ton overhead crane, a new flame deflector and fire-control system, and much new instrumentation. The job took a whole year. By January 1959, ABMA crews installed a full-sized, high-fidelity [80] mockup of the first stage in the tower to check all the interfaces for service and test equipment. Satisfied, they took the mockup out, and put in the first static-test version. The test booster, SA-T, was installed during February, and late in March the first firing test, a timid one, burned only two engines for an eight-second run. Many skeptics still doubted that the eight-engine cluster would operate satisfactorily. "People at that time still had a lot of difficulty persuading individual rocket motors to fire up... reliably," von Braun explained, "and here we said we would fire up all eight simultaneously." There were a lot of jokes about "Cluster's Last Stand," von Braun chuckled. Still, the firing crew at Marshall proceeded cautiously. Not until the third run, on 29 April 1960, did test engineers fire up all eight barrels, and then only for an eight-second burst. By the middle of June, the first stage was roaring at full power for more than two minutes.

Reverberations of the Saturn tests were quickly felt. The acoustical impact was quite evident in the immediate area around the city of Huntsville, and the long-range sound propagation occurred at distances up to 160 kilometers. The result was a rash of accidental damage to windows and wall plaster, followed by a rash of damage claims (sometimes filed by citizens on days when no tests had been conducted). Aware that climatic conditions caused very pronounced differences in noise levels and long-range sound propagation, engineers began taking meteorological soundings and installed a huge acoustical horn atop a tower in the vicinity of the test area. No ordinary tooter, the horn was over 7.6 meters long and had a huge flared aperture over 4.6 meters high. Its sonorous gawps, bounced off a network of sound recorders, gave acoustical engineers a good idea whether it was safe to fire the big rockets on overcast days.42

To make the most use of the expensive test facilities, as soon as a booster completed its test-firing series and was shipped off to Cape Canaveral for launch, the SA-T booster was fastened back into place for further verification and testing of Saturn systems. The complex test instrumentation was complemented by the growing sophistication of automatic checkout systems used in the Saturn I first stage. Early hardware was designed for manual checkout. As more advanced electronics and computers became available, significant portions of the procedure were designed for automatic tests and checks. The scope of automatic test and checkout evolved into a complex network that tied together diverse geographic test and manufacturing locations. Later generations of Saturn vehicles and individual components were electronically monitored, literally, from the time of the first buildup on the shop floor until the mission was finished in outer space.

Because manufacturing tests of individual stages occurred separately at diverse locations, a specialized facility was required to verify the [81] physical interface design, system integration, and system operation of the total vehicle. During a flight, natural structural frequencies occurred-the result of vibrations of moving parts, aerodynamic forces, and soon. If the control-force input of gimbaling engines, for example, reinforced the structure's natural frequency, the amplification of such structural deflections could destroy the vehicle. So a dynamic test stand, large enough to surround a complete two-stage Saturn I, was begun at MSFC in the summer of 1960 and finished early in 1961. The dynamic test facility was designed to test the vehicle either in entirety or in separate flight configurations. Vibration loads could be applied to the vehicle in pitch, yaw, roll, or longitudinal axis to get data on resonance frequencies and bending modes. Saturn I tests uncovered several problem areas that were then solved before launch. Matching frequencies in the gimbal structure and hydraulic system were uncovered and "decoupled." Static tests revealed weaknesses in the heat-shield curtains around the engines, so the flexible curtains were redesigned. Structural failure of the outer liquid-oxygen tanks required a reworking of the propellant flow system.43

Historically, the style of ABMA operations emphasized in-house fabrication and production, as Army arsenals had traditionally done. As the scale of the Saturn program increased, MSFC made the obvious and logical choice to turn over fabrication and manufacture to private industry. At the same time, the center retained an unusually strong in-house capability, to keep abreast of the state of the art, undertake preliminary work on new prototype hardware, and to make sure that the contractor did the job properly (for management details, see chapter 9). The do-it-yourself idea was most strongly reflected in the development of the Saturn I first stage. Ten Saturn I vehicles were built and launched; the first eight used S-I first stages manufactured by MSFC, although the fifth flight vehicle carried a contractor-built second stage (the Douglas S-IV). The last two Saturn Is to be launched had both stages supplied by private industry. Douglas supplied the S-IV upper stage, and the Chrysler Corporation's Space Division supplied the S-I lower stage.

Late in the summer of 1961, while the first Saturn I was en route to Florida for launch, MSFC began plans to select the private contractor to take over its S-I stage. The manufacturing site at Michoud was announced on 7 September, and a preliminary conference for prospective bidders occurred in New Orleans on 26 September. The first Saturn I was launched successfully one month later (27 October), and on 17 November, Chrysler was selected from five candidates to produce the S-I first stage. The final contract called for the manufacture, checkout, and test of 20 first-stage boosters. Chrysler participated in the renovation of Michoud as it tooled up for production. In the meantime, the shops at Marshall turned out the last seven S-I boosters, progressively relinquishing the primary production responsibility. During December 1961, for example,.....

[82]

....MSFC manufactured its last 1.78-meter and 2.67-meter tanks, turning over this job to Chance-Vought, of Dallas, which supplied both MSFC and Michoud as Chrysler took over the booster production.44

Chrysler, a major automotive manufacturer, was no novice to the production of rockets, having worked with the von Braun team since [83] 1954 producing Redstone rockets and their successor, the Jupiter. Chrysler easily shifted from the Saturn I to the larger Saturn IB. In July 1962, when NASA announced its intention to use the lunar orbit rendezvous, the space agency also released details on the two other Saturn vehicles. The three-stage Saturn V was planned for the lunar mission. A corollary decision called for development of an interim vehicle, the Saturn IB, to permit early testing of Apollo-Saturn hardware, such as the manned command and service modules, and the manned lunar excursion module in Earth orbit, as well as the S-IVB stage of the Saturn V. This decision permitted such flight testing a year before the Saturn V would be available. Chrysler's initial contract, completed late in 1962, called for 13 first-stage Saturn IB boosters and 8 Saturn I first-stage boosters.45

In most respects, the new S-IB first-stage booster retained the size and shape of its S-I predecessor. The upper area was modified to take the larger-diameter and heavier S-IVB upper stage, and the aerodynamic fins were redesigned for the longer and heavier vehicle. The Saturn IB mounted its eight H-I engines in the same cluster pattern as the Saturn I, although successive improvements raised the total thrust of each engine to 890 000 newtons (200 000 pounds) and then to 912 000 newtons (205 000 pounds). The thrust increase raised the overall performance of the Saturn IB; the performance was further enhanced by cutting some 9000 kilograms of weight from the stage cluster. A more compact fin design accounted for part of the reduction, along with modifications to the propellant tanks, spider beam, and other components and removal of various tubes and brackets no longer required. Additional weight savings accrued from changes in the instrument unit and S-IVB, and the insights gained from the operational flights of Saturn I. Many times, engineers came to realize designs had been too conservative-too heavy or unnecessarily redundant. The production techniques worked out for the Saturn S-I stage were directly applicable to the S-IB, so no major retooling or change in the manufacturing sequence was required. With so few basic changes in the booster configuration, existing checkout and test procedures could also be applied. At Huntsville, appropriate modifications were made to the dynamic test stand to account for the different payload configurations of the Saturn IB and the same static test stand served just as well for the S-IB first stage, although engineers reworked the stand's second test position to accept additional S-IB stages.46

During 1961-1962, several crucial decisions were completed to clarify configurations of the Saturn program and to agree on the mode to land astronauts on the moon. Once the idea of direct ascent via a Nova.....

[84]

|

|

. |

|

|

. |

|

|

| ||

....vehicle was discarded, the major issue became Earth orbital rendezvous or lunar orbital rendezvous. One of the last holdouts against LOR, Marshall eventually opted for it because it averted the multiple launches of an EOR sequence and offered the best chances for a successful mission before the end of the 1960s.

Once the issue of the mission profile had been settled, the task of developing the resources for manufacturing and testing of the Saturns became paramount, and engineers finalized the design of the Saturn I's first stage, which evolved into the first stage of the Saturn IB as well.

At this point, in the early 1960s, development of the Saturn I and IB loomed large in press releases and news stories, with special attention on [85] the lower stages. The work in this area set the baselines for manufacturing procedures, static firing tests of the multibarrel cluster, and the first launches of the Saturn I, with a live lower stage and a dummy upper stage. Because NASA and MSFC planners put such special emphasis on early static-firing tests of each stage, the engines had to be ready. From the beginning, MSFC maintained a strong effort in research, development, and production of Saturn propulsion systems. Meanwhile, parallel work on other hardware of the Saturn program proceeded: R&D on the upper stages for the Saturn I and IB (to be modified for the Saturn V); R&D for the first two stages of the mammoth Saturn V; plans for unique tooling required for production and fabrication; schemes for guidance and control of the launch vehicle. The main effort leading to large launch vehicles for manned lunar voyages was just beginning to build momentum.

![An aerial view of Marshall Space Flight Center [link to a larger picture]](p71as.jpg)

![The map shows the acoustic effects of an S-IC firing.[link to a larger picture]](p75cs.jpg)

![the drawing of the Saturn I S-I stage shows the multitank configuration. The cutaway shows the fuel baffles inside the tanks.[link to a larger picture]](p82s.jpg)