![Commonality of Saturn hardware. [link to a larger picture]](p380s.jpg)

[379] Both the Soviets and the Americans used their man-rated space rockets for a variety of missions. NASA used basic Saturn hardware for launching the Skylab space station; Skylab itself evolved from the Saturn V third stage. The last Saturn rocket to be launched culminated in the linkup of a manned American spacecraft with its manned Soviet counterpart-the Apollo-Soyuz Test Project.

Thus, one of the legacies of what started as a race in space ended in a new arena of international cooperation. The Saturn program left other legacies. The city of Huntsville, Alabama, entered a new era of social and economic vigor, since Marshall Space Flight Center's activities attracted nonspace commercial enterprises to a booming locale and injected vitality into health care, education, municipal services, and the arts. Finally, execution of the Saturn program stimulated significant research and improved technique across a wide range of fabrication and manufacturing processes.

![Commonality of Saturn hardware. [link to a larger picture]](p380s.jpg)

[381] The Apollo-Saturn program began in an atmosphere of international competition, the object of which was to beat the Russians to a manned landing on the moon. In terms of heavy payloads and successful manned flights, Soviet boosters and aeronautical sophistication seemed to set the pace for the exploration of space for several years after Sputnik. The Gemini program of the mid-1960s considerably enhanced American skills in manned space flight, and development of the Saturn I, Saturn IB, and Saturn V gave the United States a booster capability that surpassed the Soviet boosters. With the three-man Apollo spacecraft, the Apollo-Saturn combination carried not one, but seven manned missions to the lunar surface. In big boosters, where the United States had always lagged, Saturn finally retired the cup.

The Soviet space program conducted an impressive series of unmanned research missions, including remote reconnaissance and sampling of the lunar surface by robots, and the return of small samples to Earth. Yet the Russians had not landed a cosmonaut on the moon by the mid-1970s despite some spectacular manned missions, involving orbital rendezvous, docking, and crew transfer, using Soyuz spacecraft. Although the Russians successfully orbited their Salyut space station in combination with manned Soyuz launches in 1971, Soyuz 10 did not complete the transfer of the three cosmonauts and the crew of Soyuz 11 died during reentry.

In the meantime, the American space program was also moving ahead with a variety of unmanned satellites and probes, and the momentum of Saturn resulted in a genuine space station, the Skylab. The last launch of a Saturn vehicle was a singular event, achieving orbital [382] linkup of manned spacecraft-one from the U.S. and the other from the U.S.S.R.

Skylab was the final version of several plans to modify the Saturn S-IVB stage so that it could be occupied by astronauts in space. The Skylab assembly consisted of several modules, including the orbital workshop (a modified S-IVB stage), airlock module, multiple docking adapter, and Apollo telescope mount. This modular payload was launched to low Earth orbit aboard a two-stage Saturn V, with the Skylab in the upper position normally occupied by the S-IVB third stage.

The idea of using a Saturn stage as a space station apparently developed while planning Saturn I and Saturn IB mission profiles. In the normal sequence of events, S-IV and S-IVB upper stages of these vehicles became space-age "orphans." Their propellants expended, the empty stages remained uselessly in orbit. With such large tanks circling the Earth, it was not long before some thoughtful engineers wondered why it would not be possible to use an empty stage as a habitat for astronauts. In November 1962, Douglas Aircraft, the S-IVB contractor, published a short study suggesting the use of the S-IVB as a laboratory in space. A group of engineers at MSFC evidently had a parallel concept in mind, although they had not yet committed anything to paper.

During the next few years, the increasing tempo of the Apollo-Saturn program absorbed the thoughts and energies of planners at both Douglas and Marshall Space Flight Center, and nothing was accomplished in terms of turning a spent stage into a space laboratory. Early in 1965, however, program analysts at MSFC who were thinking ahead began to use the terms "spent stage" and "wet workshop" in talking about refurbishing the S-IVB in orbit and using it as a laboratory. The idea lacked programmatic approval or support until early August, when George Mueller announced the organization within Headquarters of an Apollo Applications Program Office to extend use of the hardware developed for Apollo-Saturn. Late in August, as part of Marshall's contributions to the Apollo Applications Program (AAP), a full-fledged design study was initiated to examine the concept of the spent stage laboratory and to come to some conclusions about its potential. On 1 December 1965, George Mueller gave the go-ahead for what was now called the orbital workshop, with MSFC as the lead center in the project.

The overall AAP, including the orbital workshop concept, originally contemplated a large number of both Saturn IB and Saturn V vehicles. In 1966, one early planning schedule called for 26 IB launches (primarily to carry three-man crews), and 19 Saturn V launches. Three S-IVB spent stages, three Saturn V workshops, and four Apollo telescope mounts [383] were to be orbited. Included in this ambitious schedule were five more lunar missions and two synchronous-orbit missions. The S-IVB spent stage would be converted to a lab by use of the spent-stage experiment support modules. Mounted on the forward end of the S-IVB, this module was a docking facility and airlock for the Apollo command and service modules. Because the S-IVB lacked crew quarters, the crew would live and conduct biomedical experiments in the command module, while the empty S-IVB would provide a suitable environment for familiarization with zero-g conditions in a comparatively large enclosed environment in space.1

By December 1966, plans called for a "wet" workshop, created by purging and then pressurizing the hydrogen tank in orbit to create a working environment inside. A significant addition to the scheme was an Apollo telescope mount, to be carried into orbit by another Saturn IB and connected to the orbiting workshop. Between 1967 and 1969, the plans for the workshop concept shifted with budgetary constraints and available hardware. Finally, in July 1969, Administrator Paine announced that the "wet" workshop was being dropped in favor of a "dry" workshop. Under this new approach, the workshop and the Apollo telescope mount were to be launched together by using the first two stages of the Saturn V (instead of an uprated Saturn I). All equipment, expendables, and experiments would be installed ahead of time in the workshop, ready for use when the astronaut crews made their rendezvous and docked. In August 1969, McDonnell Douglas became the contractor for two Saturn V workshops. The first workshop was scheduled for launch into a low Earth orbit sometime in 1972, with the second version serving as a backup.2

Early in 1970, NASA Headquarters announced that the AAP would henceforth be called the Skylab Program. In addition MSFC announced that the Saturn IB, carrying the three Skylab astronauts, would be launched from the modified Launch Complex 39B at Cape Kennedy. The Skylab Program at this time called for launch of the Skylab from LC 39A, followed the next day by a Saturn IB launch carrying the astronauts. The first crew was programmed to spend 28 days in orbit, and within the next six months, two more manned missions would put three-man crews into the Skylab for approximately 56 days apiece. Following these missions, Skylab would then be put into a storage mode, remaining in orbit.3

Developmental and technical problems created a delay in the anticipated launch date, which was finally rescheduled for the spring of 1973. Meanwhile the Saturn IB first stage for the first manned Skylab launch vehicle was taken out of an environmentally controlled enclosure at the Michoud Assembly Facility, where the stage had been in hibernation for three years. This particular booster was one of nine such Saturn IB stages stored at Michoud in December 1968. Altogether, four Saturn IB stages were designated for the Skylab project: AS-206, AS-207, AS-208, and [384] AS-209. Refurbishment of each vehicle was estimated at approximately 10 months. The AS-209 vehicle served as the backup stage, in case a possible rescue mission needed to be dispatched to the Skylab in orbit, using a modified CSM to return five astronauts.4

On 14 May 1973, the Skylab went into orbit aboard the AS-513 booster. Skylab was a fairly roomy space station, about as large as a medium-sized two-bedroom house, and provided a true "shirt-sleeve" environment for the astronaut crew, permitting them to live and work inside the Skylab without cumbersome space suits. NASA technicians soon realized, however, that something had gone very wrong. During the launch, a protective micrometeoroid and heat shield was torn loose, and one of the two solar power arrays, to provide electrical power to the Skylab, was also ripped away. The remaining solar wing was only partly deployed, and lack of power allowed the temperatures inside the Skylab to soar. A crash program by NASA and contractor technicians came up with a possible solution in the form of a large parasol device to deflect the sun's rays and reduce interior heat. With special equipment to set up the parasol and cut away the debris to free the solar wing, the first Skylab crew took off much later than originally planned, on 25 May 1973.

After docking, deployment of the sunshade cut the high temperatures inside Skylab, allowing the crew to move in. Still, because of the jammed solar panel, problems of temperature control and inadequate power persisted. Working outside the Skylab and using the tools brought along for this specific task, astronauts Charles Conrad, Jr., and Joseph Kerwin finally freed the power panel. The makeshift shade, plus partially restored power, reduced interior temperatures to comfortable levels, and the mission proceeded. The three-man crew spent a month in space, after adjusting to early discomfort from extended weightlessness. On their return, physicians endorsed ambitious plans for the two succeeding crews to stay up from two to three months. The second Skylab crew, launched on 18 July 1973, spent 59 days in orbit; the third crew, launched 16 November 1973, spent a record-breaking 84 consecutive days in space before splashdown on 8 February 1974. One of the major contributions of the Skylab program was convincing proof that crews could indeed spend extended period in weightlessness, perform effectively, and suffer no harmful effects on return.

In addition to these invaluable biomedical records and results, the Skylab crews conducted a wide variety of sophisticated experiments on the characteristics of the Earth's environment and resources, collected data on the sun and the solar system, and experimented with possible types of esoteric industrial processes that could be enhanced by performing them in the environment of space, avoiding the perturbing factors of the Earth's rotation and effect of gravity. Some of the more significant astronautical work during the Skylab missions involved extended observations of an unusual period of solar flare activity in 1973. Late in the....

|

.

|

|

....year, the astronauts took advantage of a target of opportunity and studied the newly discovered comet Kohoutek from their unparalleled point of view in space. In total, the Skylab missions accumulated extensive new knowledge of the oceans, weather formation and climate, pollution, and natural resources.5

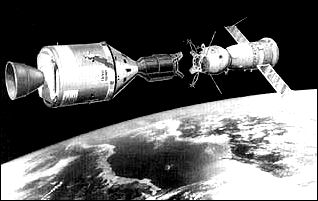

The last Saturn vehicle to be launched was AS-210, on 15 July 1975. Although the Saturns were originally developed in response to what was seen as intense Soviet competition for domination in space, the last flight of a Saturn launch vehicle featured a cooperative mission with the Soviets in space. This was the Apollo-Soyuz Test Project (ASTP). The mission involved the joining, in Earth orbit, of spacecraft of the United States and the Soviet Union. Following many months of preliminary talks and agreements, in May 1972 the Russians and Americans agreed to work out a common docking system for future generations of spacecraft, leading to the ASTP mission. The mission marked the first time that manned spacecraft of different nations met in space for cooperative engineering and scientific activities.

The ASTP launch vehicle's first stage had been built by the Chrysler Corporation at Michoud Assembly Facility in January 1967. Following static-firing tests in the spring of 1967, the stage was put in storage at Michoud, where it remained until October 1972. After the first stage was [386] modified, refurbished, and checked out, it was shipped to KSC in April 1974. After more months of storage, the first and second stages were stacked, and the vehicle was placed on the mobile launcher in January 1975. The S-IVB second stage was of the same vintage, completed in 1967 by McDonnell Douglas at Huntington Beach, California, and was stored there until the fall of 1972, when it was shipped to the Kennedy Space Center. The instrument unit, built by IBM, shared a similar manufacturing and storage history. It was shipped to KSC by barge in May 1974. After stacking, the entire vehicle was rolled out to the launch pad late in March 1975; continuous preflight checkouts and monitoring of the launch vehicle were made until launch that summer.6

The Russians were also preparing their launch vehicle and spacecraft. Considerable exchange of technical information was required between Soviet and American mission personnel. Most of these contacts concerned spacecraft, docking, telemetry, and crewmen. Even with the insights gained into Russian astronautical technology acquired as a result of the ASTP collaboration, public knowledge of Soviet launch vehicles is still sketchy in many details. As far as the engines are concerned, the Russians apparently based their propulsion systems on technology garnered from the V-2s wrested from Germany after World War II. Like the Americans, Russian technicians got their early experience in launching captured German weapons and then produced a series of modified V-2s as they began to develop their own ballistic missile technology. Early in the 1950s, the Russians evidently began work on a very large propulsion system planned for their first ICBM and considered using this propulsion system in space programs as well.

Although extrapolated from V-2 engine technology, this new Soviet engine incorporated a somewhat novel arrangement, featuring multiple combustion chambers. The physical appearance of the engine, with its quartet of combustion chambers, normally creates some confusion in the mind of an observer who associates American-style engines with a single turbopump, combustion chamber, and exhaust nozzle. In the Russian version, a single turbopump fed the oxidizer and fuel to a combination of combustion chambers. Thus, while appearing to be a cluster of engines, it is actually a cluster of four combustion chambers and exhaust nozzles. The Russians designated this propulsion system the RD-107. The RD-107 burned kerosene-type fuel and liquid oxygen, and the cluster of four combustion chambers and exit nozzles produced a total thrust of 1 000 400 newtons (224 910 pounds). The turbopump was fueled by hydrogen peroxide. This engine system did not have a gimbaling capacity, but included two small steering rockets. The Soviets produced a variant of this engine system known as the RD-108, which differed from its cousin only in the fact that it had four small steering rockets instead of two.

The combination of these engine systems as a single booster powered the series of large Soviet launch vehicles, including the Sputnik, and [387] with further variations in the upper stages, the Vostok, the Soyuz, and the Salyut space station. The basic launch vehicle was known in the United States as the type "A" booster, and it was also used by the Russians for some unmanned payloads.

The booster design situated the RD- 108 as the central core engine, also acting as a sustainer engine. Then four RD- 107 engines, with long streamlined fairings, were clustered about this central core. Integration of the parts of the launch vehicle and attaching the payload took place in horizontal position. Still horizontal, the entire vehicle was rolled out on a conveyor that resembled a railroad flatcar and positioned in the upright launch position at the launch pad. The Sputnik booster was a single-stage vehicle, although the Vostok, Soyuz, and Salyut vehicles incorporated upper stages that apparently used similar liquid oxygen and kerosene propellants. In the launch sequence, all the first-stage engines were ignited on the pad. The ignition meant a striking liftoff, with 20 main engine nozzles spouting flame, accompanied by the exhaust plumes of the 12 steering rockets. All 20 main engines continued to function during the boost phase. As propellants were depleted in the four outboard RD-107 engines, these fell away, leaving the RD-108 (the central sustainer unit), which continued to fire. Depending upon the nature of the mission programmed for the upper stages, the central core then separated from the upper-stage combination late in the boost phase, and a combination of upper stages put the payload into orbit or a space trajectory. The Russian launch vehicle, with its four elongated RD-107 streamlined units, looked rather graceful, more like a Buck-Rogers-type rocket than some of the American boosters.7

In retrospect, these Russian launch vehicles of the A series appear to somewhat less sophisticated than their American counterparts, but no less effective in getting heavy payloads into orbit. As ex-Soviet engineer and editor Leonid Vladimirov pointed out, the RD-107 system took up more space than a comparable single-chamber engine of the same power. This meant that the diameter of the first stage of the launch vehicle was also larger, resulting in a considerably greater launch weight. For this reason, the jettison of the four outboard engine systems, leaving the sustainer to carry the vehicle into orbit, was an important design feature of the Russian launch vehicles. "It was, of course, a very complicated, costly and clumsy solution of the problem," Vladimirov admitted. "But it was a solution nonetheless; all launchings of Soviet manned spacecraft and all the space-shots to Venus and Mars have been carried out with the aid of this monstrous twenty-engined cluster."

There were other interesting variations in U.S. and Soviet booster technology. The tank skins and structural elements of American vehicles kept at minimum thicknesses, shaving the weight of the structure as much as possible to enhance the payload capability. The first Western insight into the style of Soviet vehicle structure occurred in 1967, when [388] the Vostok spacecraft and booster system were put on display in Paris. The Russians series of A-type vehicles appear to have been exceedingly heavy. The Vostok launch vehicle arrived via Rouen, France, by sea, prior to shipment to Paris. To move the tank sections of the launch vehicle, workers hooked up cables to the opposite ends of the tank sections and picked them up empty, surprising many Western onlookers who expected them to buckle in the middle. Their amazement was compounded when the Soviet technicians proceeded to walk the length of these tank sections, still suspended in mid-air, without damaging them in the least. The Russian vehicles were, if anything, extremely rugged. The launching weight of the Vostok and spacecraft is still a matter of conjecture because the Soviets have not released specific numbers. Vladimirov estimated around 400 metric tons on the ground, with the greater part of the weight accounted for by the heavy engines. He drew an interesting comparison between the Soviet type A vehicle and the American launch vehicle known as the Titan:

Although the Russians never really developed a launch vehicle with the capability of the Saturn V, they apparently attempted to do so. Rumors of this new vehicle, known as type G, gained currency following a space conference in Spain in 1966. Rather than develop new, exotic high-energy propellants and propulsion systems, Soviet designers reportedly used engines from advanced ICBMs and clustered a large number of chambers to achieve high thrust. The type G booster was rolled out during the summer of 1969, but during a static test, a leak evidently began in one of the upper stages, developed into a fire, and destroyed the entire vehicle. The disastrous fire also wiped out the launch facility, including underground equipment complexes as well service towers and other support equipment at the launch site. Reports indicate that a type G vehicle was launched in midsummer of 1971, but the rocket broke up and disintegrated before reaching orbit. In November 1972, the Russians made one more attempt to launch the big type G rocket. Bad luck continued to plague the effort, and the 1972 mission also ended in disaster, apparently because of a failure in the first stage. As 1975 came to a close, development of the type G seemed to be in a state of limbo.9

Thus, the Soyuz spacecraft for ASTP relied on the time-tested type A booster. According to plan, the Russians launched first, early in the morning of 15 July, when cosmonauts Aleksey Leonov and Valery Kubasov lifted off from the Soviet Cosmodrome at Baykonur in Central Asia. Seven and a half hours later, the Saturn IB lifted off from Cape [389] Kennedy, Florida, carrying American astronauts Thomas P. Stafford, Vance Brand, and Donald K. Slayton.

The ASTP mission was a perfect finale for the Saturn program. The countdown for the launch vehicle and performance during the boost phase proceeded without a hitch. MSFC press releases noted that the Saturn IB carried the oldest engine yet flown, a nine-year-old veteran.10 After ASTP, the inventory of Saturns in storage consisted of two Saturn IB vehicles, SA-209 (backup for both the Skylab and the ASTP missions) and SA-211, and two unassigned Saturn V vehicles, SA-514 and SA-515.

|

.

|

|

[390] Behind these retired symbols of space exploration, the proficiency of MSFC persisted. With its competence in propulsion systems, Marshall was given responsibility for development and management of engines for the shuttle program, conducted R&D programs in space tracking and communications, and studied various space payloads for the future. In short, MSFC carried on a continuing influence in Huntsville and northern Alabama and in the nation's space program.

The elaboration of the nation's space program in the 1960s and early 1970s had an obvious impact in the south and southeast, anchored by major NASA centers. NASA's geographic influence in the region stretched along a great arc, from the Manned Spacecraft Center in Texas, to Marshall Space Flight Center in Alabama, to Kennedy Space Center in Florida. In between were MSFC's "satellites" near New Orleans: the Michoud Assembly Facility, the Slidell computer complex, and the Mississippi Test Facility. This concentration of space-related expertise and activities has been described as "a fertile crescent" of astronautical skills. Development of these centers of major NASA activities created extensive local and regional changes, and the story of the impact of NASA in Huntsville is paralleled in many respects by the events that occurred south of Houston and near the Kennedy Space Center.11

Before the von Braun team came to Huntsville, Alabama, the town was known as "Water Cress Capital of the World." Its population was 16 000. Even so, this period of Huntsville's "salad days" continued strong ties with the cotton textile industry, and Huntsville once boasted 13 cotton mills in the area. Throughout the 1940s, the other major source of employment in the area had been the Redstone Arsenal. Established in 1941, the 1620-square-kilometer arsenal was used by the U.S. Army in the production and testing of chemical warfare weapons. After the war, it was shut down, declared surplus property, and put up for sale in 1949. Huntsville city fathers and local politicians, including Senator John Sparkman and Representative Bob Jones, were soon sounding out their contacts in the Department of Defense to see what could be done to keep the Arsenal alive. Jones and Sparkman were hot on the trail of a new location for wind tunnel test facilities for the Air Force, but lost out to the state of Tennessee. The wind tunnel was located at the recently closed Camp Forest at Tullahoma, and was eventually named the Arnold Engineering Development Center. Nevertheless, Sparkman and Jones had made an impression. Secretary of the Air Force Stuart Symington told Sparkman that Alabama would get something better in the long run. A few weeks later, the Alabama congressmen found out exactly what they [391] were acquiring-the Army's Rocket Research and Development Suboffice, to be relocated from Fort Bliss, Texas.12

Huntsville had been one of the several sites under consideration. The site selection committee included von Braun, and he was enthusiastic about Huntsville from the beginning. "For me, it was love at first sight," he said. Among other things, the advantages of Huntsville included the existing Arsenal facilities, abundant low-cost electric power from the TVA, the Tennessee River (both for water supply and transportation), and the open space. "In selecting this site, of course," von Braun recalled, "in our field we had to consider that these rockets would be making a lot of noise."13 After the arrival of the Army's missile agency in April 1950, Huntsville started its meteoric growth, from 16 000 in 1950 to 48 000 enumerated in a special census held in 1956. The 1960 census put the population of the city at 72 000; another special census in 1964 gave the population as 123 000; in 1970 it was 136 102. Construction boomed during the first half of the 1960s: the city of Huntsville was 195th in population in the United States, but ranked 25th in building construction.

In 1950, the city limits extended about one and a half kilometers from each side of the courthouse, encompassing 11.1 square kilometers, with roughly 125 kilometers of sewer lines but no sewage treatment plant at all. Huntsville's effluent was piped to a creek outside the city limits, where it was carried directly into the Tennessee River. Tax considerations and other agreements made earlier with the textile mills provided a stumbling block to city plans for enlarging the city limits, along with improving sewage facilities-which the Army was now insisting on. After numerous sessions lasting into the early hours of the morning, representatives from the city, the Army, and the mills came to an agreement, and in 1956 the city of Huntsville suddenly enlarged itself to over 181 square kilometers. Eventually, over 1300 kilometers of sanitary lines and a first-rate sanitation system served the area.14

The influx of Army personnel, NASA civil servants, and contractors, with their families, raised enrollments in the city schools from 3000 in 1950 to over 33 000 by 1974. The numbers barely suggest the problems involved in establishing classrooms, finding teachers, and creating appropriate curricula. Fortunately, among the families of the scientists, engineers, and technicians pouring into the city were spouses with teaching backgrounds to help staff the expanding school system. The schools developed a definite scientific-technological bent, probably encouraged by the frequent appearance of many of Marshall's top personnel as guests and speakers in school classrooms and assemblies. Huntsville's new population also gave the public schools a strong orientation to higher education, with 80-95 percent of Huntsville's high school students going on to college, in comparison to a state average of only 20 [392] percent. Rapid population growth also brought new challenges to Huntsville's medical facilities. The Huntsville Hospital had been built in the 1920s. By the early 1950s, patients were being placed in the hallways of the hospital, and an emergency expansion finally brought the hospital's capacity to 150 beds. Severe pressures for medical services persisted, and by 1970, Huntsville had four hospitals in operation with a total of almost 1000 beds.15

There was a parallel impact on higher education in the city. Since 1949, the Chamber of Commerce had been advocating a branch of the University of Alabama in Huntsville. A center was authorized, and 139 part-time students began classes in January 1950. The arrival of von Braun and the elaboration of Army research immediately stimulated a graduate program. In 1960, construction of a permanent campus began at the northern edge of the city, and von Braun appeared before the Alabama legislature in support of an appeal for a $3-million bond issue to establish a research institute geared to graduate research at the new campus. The bond request was passed easily by the legislature and approved quickly by the voters, a success marking a sustained period of growth by the University of Alabama in Huntsville, with a student body of over 4000 and a replacement value of about $30 million by 1974.16

The citizens of Huntsville always maintained a strong interest in cultural activities, with literary and music societies dating back several generations. The arrival of the culturally minded German rocketeers enhanced this tradition and left an imprint on the history of the arts in Huntsville. According to local legend, the Germans arriving in Huntsville equipped themselves with library cards even before the water in their homes had been turned on. The newcomers from Fort Bliss not only appeared in public school classrooms, giving informal lectures and talks, but were regular attendees at local PTA meetings. Acculturation was remarkably rapid. Three years after arriving in Huntsville, the DAR medal for the best American history student in the city went to a young German girl.

Wanting to avoid a German enclave in the middle of the dry, von Braun encouraged his associates to settle all over Huntsville. The rocket engineers and the Huntsville natives soon established strong bonds of common interests and activities. A local chamber music group learned of the musical inclinations of many of the newcomers. The day he arrived, Werner Kuers, an accomplished violinist, was startled to receive a call to join one of the local music groups in need of a new violin. "I was very astonished," Kuers recalled. "Mr. Dreger soon started to arrange playing sessions for us in homes and churches. We were introduced into quite a number of very friendly families interested in cultural activities and education. I experienced a welcome in this city that I had never experienced before anywhere."

[393] Thus, veterans of Peenemuende and of Fort Bliss were quickly absorbed into the life of Huntsville and into American culture. In April 1955, only five years after they had arrived in Alabama, the first group of 109 Germans became American citizens. Their naturalization took place at a public ceremony in the Huntsville High School auditorium, part of the officially proclaimed events of a "New Citizens' Day" declared by the city. Many of the newly naturalized American citizens had already taken an active role in civic affairs. A sergeant in the Luftwaffe when he was assigned to Peenemuende, Walter Wiesman joined the Junior Chamber of Commerce in Huntsville soon after the von Braun team's arrival in 1950. Two years later-before Wiesman became a naturalized citizen-the JCs elected him their president.17

In Marshall Space Flight Center's heyday, wags sometimes referred to Huntsville as "Peenemuende South." For years, the city proudly called itself Rocket City, U.S.A. Nevertheless, the city fathers, as well as von Braun himself, realized that federal budgets, like NASA's, had valleys as well as crests. It was widely agreed that Huntsville should expend considerable time and energy attracting other industries into the area. In later years, von Braun took a considerable measure of satisfaction in remembering his role as an advocate of diversification. "I can say in retrospect that I have never regretted using my powers of persuasion... in talks with the city fathers and our community advisory committee, when I always reminded people: `Don't get too used to this NASA money that's flowing into this area.'" He warned against becoming a single-business town and advocated the attraction of other industries during a period of good stability, with attention to nonaerospace companies in particular.

The development of the industrial character of Huntsville frequently reflected the high-level technology represented by NASA and the U.S. Army Missile Command, on the site of the old Redstone Arsenal. The continuing development of the Cummings Research Park characterized this high-level technology. Located near the University of Alabama campus, the Research Park comprised over 30 companies that offered unique management services and research facilities and employed over 6000 people with an annual payroll of over $93 million by 1974. In the 1960s, the emphasis was on space, but the farsightedness of von Braun and other Huntsville industrial executives maintained a healthy diversity in the city's manufacturing companies in the 1970s. At the Research Park and elsewhere, including an industrial center located near the new Jetport, Huntsville's products included automobile radios, digital clocks, electronic parts, computers, TV cameras, ax handles, flags, aircraft specialty glass, tools and dies, telephones, rubber tires, and a host of other goods and services.18

One of the most visible results of the von Braun team's sojourn in Huntsville was the new Von Braun Civic Center located downtown near a [394] renewal area known as Big Spring Park. A $14- million complex that opened in 1975, the center included a large arena, as well as a spacious exhibit hall. A concert hall and playhouse provided exceptionally fine facilities for both performers and audience. Finally, the performing arts in Huntsville were no longer dependent upon the good will of various churches and high school auditoriums. The homeless graphic arts of the city at last found, in the Von Braun Center, a handsome new creative arts museum, with arrangements for both permanent and visiting art exhibits. The city also acquired a major tourist attraction, the Alabama Space and Rocket center. The Center not only coordinated tours at MSFC, but also mounted some innovative displays. Skillfully planned and automated dioramas and indoor exhibits explained the theory of the solar system, fundamentals of rocket propulsion, future space exploration, and numerous other aspects of astronautics. The indoor displays also featured an eye-catching array of aerospace hardware, including full-sized mockups of spacecraft and genuine artifacts such as Saturn engines. The most impressive section was outdoors, where a rocket display area included several Army missiles, a V-2, and several early NASA launch vehicles. Towering above them all, a Saturn I stood erect, and a complete Saturn V rocket, stretched out on its side, loomed as a backdrop.19

Spinoff

The impact of the Saturn program in Huntsville was to be expected, but there were also much broader influences. Many Americans believed that the national space program would be the source of significant products for use in everyday life. Although many products found their way into ordinary life as a result of space research, the expectations for immediate impact were probably too optimistic. In his thoughtful and provocative book, Second Order Consequences, Raymond Bauer noted that the design and development of space hardware, systems, and subsystems were specialized from the beginning. It has not always been easy, therefore, to transfer technology into the market place.20

This is certainly not to say that space technology has had no impact on American lives. In a larger sense, the operation of communications satellites, weather satellites, and environmental and resources satellites are only some examples. Biomedical research, including techniques for monitoring and analyzing an astronaut's life signs during a mission, has had a significant effect on medicine and hospital care. It has been frequently noted that the space program in general has had a tremendous influence on the electronics and computer industries in stimulating....

|

.

|

|

|

. |

|

|

|

|

|

....considerable research and providing job opportunities for thousand of workers and technicians.21

Nevertheless the technology represented by the electronics and computer industries has benefited from the space program essentially in terms of second order consequences. Much of that technology and many of the techniques were developed for highly sophisticated and complex space programs and only with some changing and adaptation were the technology and techniques found to be suitable for other civilian applications. This factor is an example of what Bauer and others have called the "intangible spinoff." Further, advances in this respect are important to [396] technology for a couple of reasons. Taken individually, these incremental improvements contribute to overall efficiency and often to higher quality in day-to-day industrial operations in the production of goods and services. As Bauer emphasized, "Although the gain from application of a new welding technique may be small, the aggregate benefits of many such advances, applied in many industries and firms, can be quite large." In addition, Bauer emphasized it was possible for new methods, new advances, and new ideas to come together in some combination that would also result in a striking or significant new advance. "The convergence of a number of such improvements, along with technical advances arising in other fields, may make possible new fundamental inventions of substantial individual significance."22

In the development of the Saturn vehicle, many spinoffs consisted of myriad improvements in the prosaic areas of shop work, although such improvements were usually the result of new fabrication technologies and use of advanced materials. William R. Lucas, a senior engineer at MSFC and later Director of the Marshall Space Flight Center, emphasized that the almost immediate usage of new aluminum alloys at MSFC undoubtedly encouraged further research and development in the field, including the development of additional alloys, thermal treatment, and fabrication processes. By the same token, new research and development work in the welding of aluminum alloys also took place.23 Consistent with Bauer's comments about the significance of the accretion of technological expertise as well as the potential impact of convergence, one welding engineer at Marshall Space Flight Center posed this rhetorical question: "What has the space program contributed to welding technology?" The engineer admitted that the question was at once blunt as well as disconcerting-disconcerting, "because many of the contributions are quite subtle, beyond the reach of symbolism, and often never recognized."24

Marshall's successful approach to welding problems was not so much a function of breathtaking or striking breakthroughs as it was a process of accretion and convergence: the application of improved techniques, thoughtful readjustment and realignment of certain modes of the operation as well as the equipment, taking a slightly different approach in the operational techniques for welding different alloys, and an increasing concern for absolute cleanliness. At Marshall Space Flight Center, a familiar statement was that "the weld may be defined as a continuous defect surrounded by parent metal." The high incidence of weld defects and high repair rates, even as late as 1967, was a continuing problem. One of the most frequent defects involved porosity. R. B. Hoppes described the situation in 1967: "In 144,000 inches [366 000 centimeters] of weld made on four Saturn V first stages, porosity accounted for 79% of the total number of defects. Cracks ranked second at 9%." The nagging problems were solved basically by the application of [397] some of the techniques and procedures outlined above, particularly cleanliness. Contaminants created most of the porosity problems, and Marshall engineers went back almost step by step through the welding process, rethinking their approach, and taking special care to eliminate any instance where contaminants might come into contact with the surfaces to be welded. It was only by this careful and conservative approach, rather than through some marvelous breakthrough, that the welding problems were finally surmounted.25

Marshall's experience in solving welding problems, along with similar information from other NASA programs, was disseminated through a series of special publications by the NASA Technology Utilization program. Fourteen published studies, for example, were sponsored by MSFC through the Battelle Memorial Institute of Columbus, Ohio. The studies described the problems of weld porosity and defects and the various steps in welding the large-scale components that were part of the Saturn V development program.26 Other NASA pamphlets resulting from the Apollo-Saturn program dealt with brazing and brazing alloys, piping and tubing, seals and sealing, insulation tools and techniques, a technique for joining and sealing dissimilar metals, and the application of magnesium lithium alloys. The electromagnetic hammer developed in the S-IC manufacturing program was used by a number of aircraft and other metal-working firms, and the contributions of the Saturn program to general technology included a publication on advanced bearing designs. The commonplace, but highly useful, parade of developments and contributions ran the gamut from better adhesives for bonding auto trim to several different kinds of computer programming, to spray foam, to new types of pipe, and better ways of doing things in a wide variety of fields.27

Saturn in Retrospect

There were numerous instances of new technological developments, some among the Saturn contractors, others involving both government and industry. The difficulties of Douglas in trying to find a good substitute for balsa wood in the S-IV and S-IVB stages is an example. North American took the lead in perfecting spray-foam insulation for the S-II second stage, including the special phenolic cutters to trim the stuff once it had cured. On the other hand, it is virtually impossible to pinpoint all the major technological innovations in Saturn, then ascribe them to personnel at Marshall or at some contractor's plant. Marshal set the specifications and guidelines, and the contractor produced the product. MSFC followed its contractors very closely, not only in paperwork, but also in hardware. Laboratories and test stands at Huntsville were not just backup facilities, they provided depth and additional manpower for problems encountered in a joint program. Thus the F-1 combustion [398] instability problem was simultaneously tackled from several angles by both NASA and Rocketdyne. The Saturn program succeeded because complications were faced and resolved; the mutual goal was to make the vehicles work, and they did.

The whole field of cryogenics changed as a result of the Saturn program, with government and industry cooperating on a number of problems. For one thing, there was the sheer volume of production of cryogenic materials, storage, transportation, and many technical problems of piping it from one point to another at test sites and at the launch pad. Computer operations and related software were affected by the influence of Saturn requirements for test, checkout, and launch, which led, among other things, to the new computer language called ATOLL (Acceptance Test or Launch Language). Demands for unparalleled compactness and reliability in Saturn guidance and control resulted in instrument unit innovations such as unit logic devices and triple modular redundancy. As a part of the effort to keep weight at the minimum, guidance and control components in the instrument unit were fabricated from beryllium and magnesium-lithium alloys, the first application of these materials, which are difficult to work with, in the space program.

The unusually large dimensions of Saturn components posed recurrent complications. In developing the S-IC stage, production of the large skin panels depended on refinement of existing techniques of metals fabrication and forming, but even more in the manner and utilization of oversized tooling never accomplished before. In fact, in dealing with the technology of the Saturns in general, the most consistent factor seemed to be the enormous size of the vehicles. Time after time, when engineers and technicians were pressed to define what was "new" about the Saturn, what fantastic new technological techniques were applied in its development, personnel would shake their heads and invariably comment on size.28 Size was a factor in tooling as well as in welding exotic space-age alloys, especially in the case of the S-II stage. Even though every attempt was made to use off-the-shelf hardware and existing technology, Saturn's size implied new requirements and new complications. It just was not possible, for example, to take an H-1 engine and easily uprate it to the thrust of an F-1 engine. The extrapolation of existing technology simply did not work when the engines got into the operational regimes of higher flow rates, pressures, and the associated wear and tear on the engine machinery.

Saturn logistics generated unexpected difficulties. Prior to the Saturn program, rockets could be moved from factory to test site to launch pad by conventional means, such as available highway, water, or air transport. Saturn used these transport modes as well, but required oversized equipment, custom-built or modified for the job.

In terms of management, NASA seems to have borrowed, albeit with permutations, bits and pieces of managerial techniques from industry, [399] business, and the military. What NASA (and particularly Marshall Space Flight Center) apparently added was "visibility," in terms of progress and problems, as well as of the individual responsible for handling these aspects. Visibility, both for the product and for personnel, was the prime concern of the Program Control Center of Arthur Rudolph's Saturn V Program Office. Its success in tracking the myriad bits and pieces of Saturn vehicles impressed even NASA Administrator Webb, who prided himself on managerial techniques and skills. Claiming that MSFC was unusually thorough in its management may seem like a simplification. Given the diversity of the prime contractors and their armies of subcontractors and vendors, however, the clockwork efficiency and the reliability of the Saturn vehicles were remarkable. Meticulous attention to details, and keeping track of them, was a hallmark of MSFC.

It is worth noting that even after the Saturn V program was over, MSFC still received many requests from businesses and managers asking "how did you do it?" Here again it is probably wise to remember Bauer's admonition that space management, just like space hardware, has been frequently developed to meet particular and complex problems, not always compatible with the outside, or commercial, world.

In retrospect it seems that the impact of the Saturn program, in terms of spinoff, was best observed in improved industrial technique, in basic shop practices, and in the frequently prosaic but necessary areas of how to run machine tools, how to bend tubes, how to make and apply fasteners, and simply how to get around in a machine shop. This was part of Marshall's heritage anyhow. It must be remembered that the von Braun team came directly out of the Army tradition of the in-house arsenal philosophy, and that Marshall not only built the first of the Saturn I vehicles, but the first few S-IC first stages as well. Even though they did not get into the construction of S-II, S-IV, and S-IVB stages and their engines, Marshall consistently retained the in-house capability of duplicating test programs and even major parts of such hardware. As Lee James noted, it was difficult to make this kind of concept acceptable, and work effectively with the contractor. Marshall somehow carried it off.

The Apollo-Saturn program frequently used the overworked phrase, "government-industry team" in explaining how the Saturn program was carried out successfully. It would be easy to underestimate this phrase as a, bit of public relations flak put out by the space centers as well as the manufacturers themselves. Such does not seem to be the case. It was not unusual, in the course of interviews with contractor and NASA personnel, to name someone who had been interviewed previously on a related topic. The mention would bring about a quick smile and a brightening of the eyes and a response like "Oh, do you know so and so? Yes, we worked on....followed by one or two anecdotes indicating a feeling of exceedingly strong partnership. Government and contractor personnel actually did relate to each other, especially at the technical levels. This ingredient [400] had to be important to the success of the program. It meant that individuals could easily call each other on the phone, discuss a problem, agree on a solution, and continue the work without major interruption.

The overall success of the Saturn program depended on a significant number of key decisions. One of these would have to be the decision in 1957 to start consideration of the clustered engine concept as a means to get heavy payloads into orbit. As natural as this concept seems today, it has to be remembered that the tricky nature and recalcitrant operating characteristics of rocket engines at that time suggested clustering of two or more engines would be courting absolute disaster. Next was the decision to use liquid hydrogen as one of the propellants. The application of this high-energy fuel made all the difference in the performance of the Saturn I, Saturn IB, and Saturn V vehicles. The use of the fuel allowed optimum sizing of the stages while keeping the weight to a minimum, so that a three-astronaut payload could be carried successfully into orbit and boosted into lunar trajectory. The controversy of EOR-LOR also stands out as a major period of decision early in the program. The choice of LOR led to the successful Saturn IB interim vehicle and stabilized the design configuration of the Saturn V. Finally, the decision to adopt the all-up concept stands out as one of the steps that permitted the United States to achieve the manned lunar landing on the moon before the end of the 1960s.

It is interesting to note that the von Braun team argued about the acceptance of three of these four major program milestones. On the other hand, the argument seems to have been one of degree rather than one of substance. Despite the strong recollections of individuals who say that von Braun opposed liquid hydrogen from the beginning, one must remember that LH2 had been included very early by MFSC-in terms of the Centaur upper stage-in some of the early Saturn system studies.

The collective technological experience of the Saturn program was effectively applied in planning the Shuttle program, most notably in the Shuttle's propellant and propulsion systems. Marshall's experience in the handling and pumping of cryogenics, construction of fuel tanks, and development of the LH2 engines were directly applied to the Shuttle concept.29

In one respect, the technology of the Saturn vehicle represented the closing of a circle in international space partnership and cooperation. Allies in World War II, the U.S. and the U.S.S.R. both borrowed heavily from the technological storehouse of their defeated foe, Germany. In the early postwar years, both the U.S. and the U.S.S.R. learned from firing their respective stocks of captured V-2 rockets and perfected significant sectors of their own new rocket technology out of the V-2 experience common to both. This propulsion technology was further elaborated during the Cold War era along an escalating front of improved ICBM weaponry. When landing on the moon became an acknowledged race, [401] both borrowed liberally from the extant technology of ICBM propulsion systems to build large rocket boosters. Tempered in wars both hot and cold, the technological heritage of the launch vehicles that put the Apollo-Soyuz Test Project into orbit could be traced back to the German technicians of World War II. The former wartime allies were now closing a technological circle that had ranged from partners, to protagonists, to partners again, with German expertise in rocketry as a catalyst.

Partnership in space, by itself, will be no automatic guarantee of international amity. Partnership in space exploration may be an exhilarating prospect, however, offering an additional incentive for international cooperation and peace. If so, then the Saturn program may count this factor as its most important legacy.