Advanced Design, Fabrication, and Testing

June 1965

1965

June 1

ASPO Manager Joseph F. Shea replied to a recommendation by the

Assistant Director for Flight Operations to incorporate warning lights in Block

I and II CMs to indicate failure of the gimbal actuator secondary drive motors.

ASPO decided that no failure indication would be provided for the redundant

drive motors in Block I spacecraft because:

- in-flight checkout procedures would provide for exercising the gimbal

actuators by the primary and secondary drive motors prior to service

propulsion system burns; and

- all manned Block I missions would be conducted in earth orbit and reaction

control system deorbit capability was stipulated.

The warning lights

would be incorporated in Block II spacecraft, and the in-flight checkout

procedures would also apply to Block II lunar missions.

Memorandum, Joseph F. Shea, MSC, to Assistant Director for Flight Operations,

"Service Propulsion System (SPS) Secondary Gimbal Motor Fail Indication," June

1, 1965.

June 2

In an attempt to reduce the overall preflight time in connection

with lunar landing research vehicle (LLRV) activities, a meeting was held at

Flight Research Center. Principal participants were Ray White, Leroy Frost,

Leonard Ferrier, Joe Walker, Don Mallick, Cal Jarvis, Jim Adkins, Zeon Zwink,

Wayne Ottinger, and Gene Matranga.

The session commenced with an estimate of time required to perform each of

the functions on the preflight checklist. Review indicated that preflight might

be shortened in several ways:

- since the radar altimeter and doppler radar units did not affect safety of

flights, it was suggested that radar checks on flight mornings be reduced to a

minimum or be performed without inspection coverage;

- addition of ac and dc voltmeters in the cockpit would eliminate need for

power checks during the avionics preflight;

- when the weight and drag computer had been properly checked in flight, the

weight and drag preflight check could be streamlined down from the 30 minutes

currently required; and

- investigate the need to refill H2O2 after prime.

In general, though

several operations were performed simultaneously during most of preflight, it

appeared other operations could be performed in parallel and thereby reduce

overall preflight time. Memorandum for Files, "LLRV Preflight Procedures," Gene

J. Matranga, June 2, 1965.

June 2

ASPO advised North American that, at present, no unmanned flights

were planned for the Block II CM. After the company concluded its own analysis

of Apollo requirements, MSC would determine whether the heatshield must be

verified prior to manned missions. But because of the long "lead time" involved,

North American should continue securing the requisite instrumentation pending a

final decision.

TWX, C. L. Taylor, MSC, to NAA, Space and Information Systems Division, Attn:

J. C. Cozad, subject: "Requirements for Mission Programmers and Heat Shield

Measurements in Block II CSM," June 2, 1965.

June 3

Northrop-Ventura began qualification testing of the earth landing

system for Apollo with a drop of boilerplate 19 at El Centro, Calif. The entire

landing sequence took place as planned; all parachutes performed well.

"Apollo Monthly Progress Report," SID 62-300-38, pp. 2-3.

June 6

NASA launched Gemini IV, America's second multi-manned space

mission, piloted by astronauts James A. McDivitt and Edward H. White II, from

Cape Kennedy. Gemini IV's primary objective was to evaluate the performance of

man and machine during prolonged space flight. Also during this flight, White

opened the hatch on his spacecraft and performed America's first "space walk."

On June 7, after four days in space, McDivitt and White landed their vehicle in

the Atlantic Ocean some 724 km (450 mi) east of the Cape.

James M. Grimwood and Barton C. Hacker with Peter J. Vorzimmer, Project

Gemini Technology and Operations: A Chronology (NASA SP-4002, 1969), pp.

200-202.

June 3-10

MSC approved North American's recommendation that a programmer

timer approach be used for earth reacquisition by the CSM's S-band high-gain

antenna.

"ASPO Weekly Management Report, June 3-10, 1965."

June 5

ASPO Manager Joseph F. Shea concluded, after reviewing the

boilerplate 22 mission, that all the test objectives would be met satisfactorily

either in the flight of spacecraft 002 or in the ground qualification program.

For that reason the boilerplate 22 flight would not be repeated. Memorandum,

Shea to Distr., "Test Objectives," June 5, 1965.

June 6-12

ASPO reported a number of significant activities in its Weekly

Activity Report.

- The CSM design engineering inspection was satisfactorily conducted at

North American June 8-10.

- Qualification of the Apollo standard initiator was successfully completed

by Space Ordnance Systems, Inc.

- The first full systems firing of the LEM ascent engine was accomplished at

Bell Aerosystems using the heavyweight ascent (HA)-2 propulsion test rig.

- The LEM development program was revised and LEM test article (LTA)-4,

LTA-5 ascent stage, flight test article (FTA)-1, and FTA-2 were

eliminated.

"Weekly Activity Report, June 6-12, 1965,"sgd. Joseph F.

Shea.

June 7

George E. Mueller, Associate Administrator for Manned Space

Flight, approved procurement of the lunar surface experiments package (LSEP).

The package, to be deployed on the moon by each LEM crew that landed there,

would transmit geophysical and other scientific data back to earth. NASA's

Office of Space Science and Applications would make the final selection of

experiments. Mueller emphasized that the LSEP must be ready in time for the

first lunar landing mission. Management responsibility for the project was

assigned to MSC's Experiments Program Office.

Memorandum, George E. Mueller, NASA, to MSC, Attn: Dave Lang, "Request for

Approval of Procurement Plan for Lunar Surface Experiments Package," June 7,

1965; NASA OMSF, Apollo Program Directive No. 3, "Management Assignment for the

Lunar Surface Experiments Package (LSEP) Project," June 15, 1965.

June 7

Apollo Program Director Samuel C. Phillips approved MSC's request

for revised velocity budgets for the two spacecraft. It was understood that

these new values would:

- still meet the free return trajectory constraint; and

- increase (to at least two degrees) the LEM's out-of-plane launch

capability. MPAD/FOD provided the analysis and recommendations leading to this

decision.

Letter, Samuel C. Phillips, NASA, to MSC, Attn: Director,

ASPO, "Revised Apollo Spacecraft Delta V Budget (U), per letter dated May 18,

1965, Reference PS8/L-82/65," June 7, 1965; Memorandum, Carl R. Huss, JSC, to

JSC Historical Office, "Comments on Volume III of The Apollo Spacecraft: A

Chronology," June 6, 1973.

June 7

MSC directed NAA to make a "predesign" study of a rocket landing

system for the Block II CM. (The Center had already studied the system's

feasibility and had conducted full-scale drop tests.)

Letter, C. L. Taylor, MSC, to NAA, Space and Information Systems Division,

Attn: J. C. Cozad, "Contract NAS 9-150, CM Rocket Landing System Study Meeting,

15 June 1965," June 22, 1965, with enclosure, "Minutes of Rocket Landing System

Study Meeting," June 15, 1965; TWX, J. C. Ellis, NAA, to NASA Headquarters,

Attn: Director, Procurement and Supply Division, July 15, 1965.

June 7-13

North American's Rocketdyne Division began qualification

testing on the CM's reaction control system engines.

NAA, "Project Apollo Spacecraft Test Program Weekly Activity Report (Period 7

June 1965 through 13 June 1965)," p. 3.

June 8

Russia launched Luna VI, an instrumented moon probe.

Tass reported that all onboard equipment was functioning normally. Two days into

the flight, however, the spacecraft's engine failed to shut down following a

midcourse correction. This failure caused Luna VI to miss its

target by more than 160,000 km (99,419 mi).

Space Business Daily, June 11, 1965, p. 216; Tikhonravov,

et al., Ten Years of Space Research in the USSR, p.

17.

June 8-10

MSC reviewed a lighting mockup of the crew compartment in the

Block II CM. The design concept, though needing further refinement, was deemed

acceptable. Engineers from Crew Systems Division found that lights on the

fingertips of the suit gloves worked quite well; optimum positioning was as yet

undetermined, however. At the same time, MSC reviewed the design of the Block I

side hatch (i.e., not modified to meet Block II extravehicular requirements).

Reviewers found North American's major problems were warpage and crew ingress

from space. Further, the design of both side hatches needed "additional

coordination" with that of the umbilical access arm of the launch tower to

ensure compatibility.

"ASPO Weekly Management Report, June 3-10, 1965"; "ASPO Weekly Management

Report, June 10-17, 1965."

June 9

Crew Systems Division reported that MSC had ordered Hamilton

Standard to integrate seven layers of thermal protection into the A5H pressure

suit.

Memorandum, Francis J. DeVos and William C. Kincaide, MSC, to Record,

"Meeting on June 9, 1965, to discuss thermal and meteoroid protection for the

Apollo Extravehicular Mobility Unit," June 22, 1965.

June 10-17

Crew Systems Division reported that, as currently designed,

the environmental control system (ECS) in the LEM would not afford adequate

thermal control for an all-battery spacecraft. Grumman was investigating several

methods for improving the ECS's thermal capability, and was to recommend a

modified configuration for the coolant loop.

Memorandum, Owen E. Maynard, MSC, to Distr., "LEM battery thermal control

problem," June 17, 1965.

June 10-17

NASA hired the U.S. Navy's Air Crew Equipment Laboratory

(ACEL) to study several physiological aspects of pure-oxygen environments.

Primarily, ACEL's study would try to determine: (1) whether known effects (such

as lung collapse) could somehow be reversed; and (2) whether such environments

enhanced respiratory infections.

"ASPO Weekly Management Report, June 10-17, 1965."

June 10-17

A list of materials that North American reported using in the

CM's habitable area omitted more than 70 items that had appeared in earlier such

reports. MSC ordered the company to determine why. This item could affect the

course of backup toxicity testing. Materials listed as "used but not tested"

were given highest priority in toxicity testing.

Ibid.

June 11

MSC ordered Grumman to propose a gaseous oxygen storage

configuration for the LEM's environmental control system (ECS), including all

oxygen requirements and system weights. Because no decision was yet made on

simultaneous surface excursions by the crew, Grumman should design the LEM's ECS

for either one-or two-man operations. And the Center further defined

requirements for cabin repressurizations and replenishment of the portable life

support systems. Oxygen quantities and pressures would be worked out on the

basis of these ground rules. (See July 1-8.)

TWX, R. Wayne Young, MSC, to GAEC, Attn: R. S. Mullaney, June 11, 1965.

June 11

The question of whether a data tape recorder would be installed

on LEM-1 had been discussed at several Apollo 206 Mission Operations Plan

meetings and there was a strong possibility it would not be installed.

In a memorandum to ASPO Manager Joseph F. Shea, Assistant Director for Flight

Operations Christopher C. Kraft, Jr., pointed out that his Directorate had

responsibility to ASPO of insuring "that all possible test objectives are

accomplished. This is done not only by real-time conduct of the mission, but

also through considerable premission planning which integrates the desired

profile with the Manned Space Flight Network. The underlying purpose of all

these operations activities is the accumulation of data, which for unmanned,

nonrecoverable spacecraft such as LEM-1 can only be provided through the use of

RE telemetry. The FOD (Flight Operations Directorate) does not believe the

Apollo 206A Mission Objectives can be assured of being accomplished without the

addition of a data tape recorder and associated playback transmitter. . . ."

Kraft said the tradeoff of weight and cost of a data recorder and dump

transmitter versus possible loss of data for primary mission objectives,

considering the cost of a Saturn IB launch vehicle, a fully functional LEM

spacecraft, and the ground support required, seemed inequitable. He recommended

that a data tape recorder and associated playback transmitter be installed on

LEM-1 (and 2) to ensure that test objectives were achieved.

Memorandum, Kraft to Shea,"LEM-1 Mission 206A Data Tape Recorder," June 11,

1965.

June 11

ASPO Manager Joseph F. Shea, in a memorandum to Robert Williams,

said that, confirming their discussion with Christopher C. Kraft, Jr., and

Donald K. Slayton, both had agreed that HE orbital communications in the Block

II Apollo spacecraft were not needed. Shea asked Williams to look into the

implications of removing the requirement.

Memorandum, Shea to Williams, "Block II communication system," June 12, 1965.

June 11

MSC and North American discussed the brittleness of the boost

protective cover and the possibility that, during tower jettison or abort, the

cover might break up and cause damage to the spacecraft. Having investigated a

number of various materials and construction techniques, North American

recommended adding a nylon fabric to strengthen the structure. Company engineers

believed that, thus reinforced, the cover would be less likely to tear apart in

flight. Even though this would increase the weight of the cover by about 27 kg

(60 lbs), MSC concurred. The change applied to both Block I and Block II CMs,

and was effective for spacecraft 002, 009, and all subsequent vehicles.

Letter, C. L. Taylor, MSC, to NAA, Space and Information Systems Division,

Attn: J. C. Cozad, "Contract NAS 9-150, Implementation of Actions Recommended at

the NASA/NAA Boost Protective Cover Problem Area Review at MSC June 11, 1965,"

June 21, 1965, with enclosure: "Abstract of Proceedings, NASA/NAA Boost

Protective Cover Problem Area Review, MSC, June 11, 1965," June 14, 1965;

memorandum, Owen E. Maynard, MSC, to Chief, Structures and Mechanics Division,

"Action Items resulting from Boost Protective Cover Problem Area Review at MSC,

June 11, 1965," June 15, 1965; memorandum, Maynard, to Chief, C&SM Contract

Engineering Branch, "CCA to NAA on backing material for Boost Protective Cover,"

June 24, 1965.

June 12

Apollo Program Director Samuel C. Phillips listed the RE

communications systems envisioned by NASA Headquarters on the first three

R&D LEMs and requested ASPO Manager Joseph F. Shea's comments.

The first three LEMs (LEM-1, LEM-2, and LEM-3) would be equipped with

communications equipment in addition to that required in the LEM for lunar

missions to provide:

- transmission of required engineering (R&D) data;

- redundant operational telemetry;

- updating of spacecraft equipment via an up-data command link; and

- redundant tracking capability.

The LEM R&D communications

system was essentially independent from the operational communications systems.

It would be housed primarily in the equipment bay (which on operational flights

would house the scientific payload equipment).

Letter, Phillips to Shea, "R&D Communications and Tracking systems in

LEMs 1, 2, 3," June 12, 1965.

June 12

Samuel C. Phillips, Apollo Program Director, noted MSC request

for support from Goddard Space Flight Center on LEM battery development as well

as Goddard's agreement to furnish limited support.

Phillips suggested to ASPO Manager Joseph F. Shea that since MSFC had much

experience in the design, development, and operational aspects of battery

systems, it was important to use their experience and recommended MSFC be

contacted if such action had not already occurred.

Memorandum, Phillips to Shea, "LEM Battery Development," June 12, 1965.

June 14

MSC Director Robert R. Gilruth appointed a Technical Working

Committee, headed by Edwin Samfield, to oversee the design of a Lunar Sample

Receiving Laboratory at the Center.

Memorandum, Robert R. Gilruth, MSC, to Chief, Engineering Division,

"Formation of a Technical Working Committee for the design of a Lunar Sample

Receiving Laboratory and designation of consultants to assist in the selection

of an architect-engineer firm," June 14, 1965.

June 14-15

Using a LEM mockup at Grumman, and with the assistance of

astronauts Roger B. Chaffee and Donn F. Eisele, engineers from Hamilton Standard

performed mobility tests of the reconfigured portable life support system

(PLSS). Crew Systems Division (CSD) reported that the reshaped back pack did not

hinder entering or leaving the spacecraft; and while some interference problems

were inescapable when the PLSSs were worn inside the spacecraft for any period

of time, CSD believed that damage could be prevented through training and by

limiting movement by the crew. Grumman, however, contended that the newer PLSSs

had "serious implications" for mobility inside the LEM.

GAEC, "Monthly Progress Report No. 29," LPR-10-45, July 10, 1965, p. 3; "ASPO

Weekly Management Report, June 10-17, 1965"; MSC, "ASPO Weekly Management

Report, June 17-24, 1965."

June 15

Independent studies were made at MSC and North American to

determine effects and impact of off-loading certain Block II service propulsion

system components for Saturn IB missions. The contractor was requested to

determine the weight change involved and schedule and cost impact of removing

one oxidizer tank, one fuel tank, one helium tank and all associated hardware

(fuel and oxidizer transfer lines, propellant quantity sensors and certain

gaging wire harnesses) from CSM 101 and CSM 103. The MSC study was oriented

toward determining technical problems associated with such a change and the

effects on spacecraft operational requirements.

The service module.

The North American study indicated that removing the equipment would save

about 690 000, along with a weight reduction of approximately 454 kg (1,000

lbs). Their report also indicated there would be no schedule impact provided

go-ahead was given for CSM 101 prior to June 1, 1965, and for CSM 103 prior to

November 1, 1965.

The MSC study indicated a maximum burn limitation of 280 seconds, due to

excessive drop in helium temperature; and also pointed out that the change to

the gaging system might not be as simple as North American stated because of the

arrangement of the secondary sensing system. However, those problems did not

appear insurmountable.

Memorandum, Owen E. Maynard, MSC, to Manager, ASPO, Attn: W. A. Lee,

"OffLoading Block II SPS Components for Saturn IB Missions," June 15, 1965.

June 15-18

In a series of meetings at Downey, Calif., MSC, Grumman, and

North American worked out most of the interface between the two spacecraft.

Among the most significant items yet unresolved were: the thermal environment of

the LEM during boost; and the structural loads and bending modes between the

docked spacecraft.

Letter, C. L. Taylor, MSC, to NAA, Space and Information Systems Division,

Attn: J. C. Cozad, "Contract NAS 9-150, Resolution of CSM/LEM Interfaces,

MSC/NAA/GAEC Coordination Meetings No. 27 and 29, June 15-18 and June 24-25,

1965, respectively," July 28, 1965, with enclosure: "Minutes of Coordination

Meeting . . . ," June 24-25, 1965; "Monthly Progress Report No. 29," LPR-10-45,

p. 1.

June 16

At Bethpage, N.Y., officials from Grumman and the Flight

Projects Division (FPD) discussed the status of LEM-1. During early May, the

company had agreed to devise a comprehensive development plan for the

spacecraft, one that included hardware status; manufacturing and checkout

sequences; requirements for facilities, ground support equipment, and software;

and projected schedules. By mid-June, Grumman was still unprepared to discuss

details, however, and requested another month to work on the plan. FPD could no

longer remain patient: "It is the intention of this office," the division

reported to ASPO, "to conduct a monthly LEM-1 status meeting . . . until the

LEM-1 program plan is clearly defined."

Memorandum, J. Thomas Markley, MSC, to H. L. Reynolds, "Detailed LEM-1

working schedule," June 7, 1965; letter, R. Wayne Young, MSC, to GAEC, Attn: R.

S. Mullaney, "Contract NAS 9-1100, LEM-1 Status Meeting," June 25, 1965; "ASPO

Weekly Management Report, June 10-17, 1965."

June 16

To prevent the CSM's contacting the LEM's radar antenna (a

problem disclosed during docking simulations), deviations in the CSM's roll

attitude would be limited to eight degrees or less.

"ASPO Weekly Management Report, June 17-24, 1965."

June 16

MSC ordered North American to revise the deployment angles of

the adapter panels: 45 degrees for separation, docking, and LEM withdrawal; and

- at most - 60 degrees for abort separation. (See December 7, 1964.)

Letter, J. B. Alldredge, MSC, to NAA, Space and Information Systems Division,

"Contract Change Authorization No. 275, Revision 1," June 16, 1965; letter, H.

G. Osbon, NAA, to NASA MSC, Attn: C. L. Taylor, "Contract NAS 9-150, R&D for

Project Apollo Spacecraft Results of Action Item from Eleventh Flight Mechanics,

Dynamics, Guidance and Control Panel Meeting," June 29, 1965, with enclosure.

June 16

MSC directed Grumman to modify the LEM's pulse code modulation

and timing electronics assembly to enable it to telemeter data from the abort

electronics assembly (AEA). Thus, if data from the AEA disagreed with those from

the spacecraft's guidance computer, the two sets could be reconciled on the

ground (using inputs from the Manned Space Flight Network), relieving the

astronauts of this chore.

Letter, James L. Neal, MSC, to GAEC, Attn: John C. Snedeker, "Contract NAS

9-1100, Contract Change Authorization No. 112, Provide Capability in PCMTEA to

Telemeter AGS Computer Digital Data," June 16, 1965.

June 16

The net effect of a decision by ASPO Manager Joseph F. Shea in

May was that the total fuel cell effort at both Pratt and Whitney and North

American should be no more than $9.7 million during FY 1966. The decision as to

the distribution of the funds was left to the discretion of the fuel cell

subsystem manager.

Memorandum for Record, J. Thomas Markley, "C&SM Fuel Cell Effort," June

16, 1965.

June 16-23

Structures and Mechanics Division (SMD) reported that Grumman

had found two thermal problems with the LEM:

- On the basis of current predictions, the spacecraft's skin and several

antennas would overheat during the boost phase of the mission. SMD engineers,

after analyzing the problem, believed that an "acceptable LEM environment"

could be achieved by lessening the heat transferred from the inner panels of

the adapter and by increasing that emitted by the outer panels.

- Also, Grumman had reported that, when exposed to exhaust plumes from the

SM's reaction control engines, the LEM's skin would overheat in about five

seconds. "Since the LEM withdrawal . . . requires 20 to 26 sec RCS firing,"

SMD understated, "it is apparent that a problem exists." One suggested

solution involved improved insulation.

"ASPO Weekly Management Report,

June 17-24, 1965"; memorandum, Joseph N. Kotanchik, MSC, "Review of requirement

for Grumman Aircraft Engineering Corporation (GAEC) ground support equipment

(GSE) Item LDW-410-12050, Thermal Control System," June 30, 1965.

June 16-July 15

North American submitted a design proposal for a

scientific airlock for the CM (applicable to 014 and all Block II spacecraft).

Structural design was scheduled to begin shortly.

NAA, "Apollo Monthly Progress Report," SID 62-300-39, August 1, 1965, p. 4.

June 16-July 15

North American reported two service propulsion engine

failures at AEDC and a third at WSMR. At the first location, both failures were

attributed to separation of the thrust chamber from the injector assembly; in

the latter instance, weld deficiencies were the culprit. Analysis of all these

failures was continuing.

Ibid., p. 11.

June 17

MSC directed Hamilton Standard Division to study the feasibility

of incorporating a manual override in the current pressure relief valve. During

lunar surface activity, a failed relief valve would prevent further operation of

the suit.

TWX, Richard S. Johnston, MSC, to Hamilton Standard Division, Attn: R. E.

Breeding, June 17, 1965.

June 17

Officials from Bellcomm, MSFC, and the Apollo offices in Houston

and in Washington planned primary and alternate missions for the Saturn IB

(applicable to SA-201 through SA-208). On July 16, the Office of Manned Space

Flight specified launch vehicles (both Saturn IB and V hardware) for Apollo

missions.

NASA OMSF, Apollo Program Directive No. 4, "Apollo Controlled Milestones and

Hardware Quantities - Change Approval," July 16, 1965; memorandum, B. Kaskey,

Bellcomm, to File, "Apollo Alternate Missions Meeting, Case 217 (U)," June 22,

1965.

June 17

A Development Engineering Inspection (DEI) was held on

spacecraft 002 at North American, Downey, California. The NASA Board consisted

of W. M. Bland, Jr., Chairman; R. H. Ridnour, J. Chamberlin, S. A. Sjoberg, F.

J. Bailey, O. G. Morris, O. E. Maynard, and O. Tarango.

A total of 20 Request for Changes (RFCs) were submitted and reviewed; 12 of

them resulted from the design review conducted at MSC prior to the DEI, and

eight resulted from the inspection of the vehicle. The final disposition of the

RFCs was: seven approved for immediate action; five approved for study; three

rejected; and five determined not applicable.

Memorandum, W. M. Bland, Jr., MSC to Distr., "Results of Spacecraft 002

Development Engineering Inspection," sgd. E. M. Fields, June 23, 1965.

June 17

Crew Systems Division engineers evaluated various battery

combinations for the portable life support system. The division recommended a

three-hr main and a one-hr backup arrangement, which would save about 9 kg (20

lbs) in the total weight of the vehicle.

Memorandum, Richard S. Johnston, MSC, to Chief, Systems Engineering Division,

"PLSS battery sizing," June 17, 1965.

June 17-24

NASA representatives briefed officials from the Atomic Energy

Commission on the Apollo experiments program and discussed means of coordinating

the Commission's work on a radioisotope generator to power those experiments.

"ASPO Weekly Management Report, June 17-24, 1965."

June 17-24

Crew Systems Division began evaluating space suits for the

Apollo program (submitted by Hamilton Standard, David Clark, and International

Latex. (See July 8-15.)

Ibid.

June 21

North American's Rocketdyne Division conducted the 1,000th test

firing of the Saturn V's first-stage engine, the F-1, MSFC.

Space Business Daily, June 23, 1965, p. 275; History of

Marshall. . . January 1-December 31, 1965, p. 240.

June 21

Joseph F. Shea, ASPO Manager, established as a firm mission

requirement the capability to connect the space suit to the LEM's environmental

system and to the portable life support system while in a vacuum. This

capability was essential for operational flexibility on the moon's surface.

Memorandum, Joseph F. Shea, MSC, to Chief, Crew Systems Division, "Suit

Connections," June 21, 1965.

June 21

The following definitions were specified for use in evaluating

design reliability, for design tradeoff studies, and in appropriate Interface

Control Documentation:

- Mission success

- all primary mission objectives must have been accomplished and both the

crew and command module safely recovered.

- Alternate mission

- if a contingency prevented completion of all primary mission objectives,

but did not require immediate termination of the mission, an alternate mission

plan would be followed but alternate missions would not be included in design

reliability calculations.

- Abort

- the only objective after an abort decision was the safest recovery of the

crew considering the contingency which caused the abort.

Memorandum,

William A. Lee and Harry L. Reynolds, MSC, to Chief, Systems Engineering

Division, "Mission success and crew safety definitions," June 21, 1965.

June 21-July 1

Crew Systems Division (CSD) conducted a series of flight

tests to determine whether the cabin layout of the LEM was suitable for crew

performance in zero and one-sixth g environments. Together with its report of

satisfactory results, the division made several observations that it thought

"appropriate":

- CSD suggested hand grips in a number of places to aid the crew

- Additional restraints were needed to supplement the Velcro pile on the

cabin floor

- Some problems with crew performance and mobility, present during one-g

simulations, were absent in low- or zero-g environments (e.g., moving from one

crew station to another).

MSC, "ASPO Weekly Management Report, July

8-15, 1965."

June 22

MSC advised Grumman of additional functions for the computer in

the LEM's abort guidance section (to be added only if a part of its memory was

left over after the basic requirements were digested). These functions, in order

of priority, MSC listed as:

- Midcourse corrections

- Automatic abort from a coasting descent

- Display of CSM-LEM range and range rate

- Automatic terminal rendezvous (with manual velocity

control).

Letter, R. Wayne Young, MSC, to GAEC, Attn: R. S. Mullaney,

"Contract NAS 9-1100, LEM Abort Guidance Section Functional Requirements," June

22, 1965.

June 22

NASA Headquarters established an Ad Hoc Surveyor Orbiter

Utilization Committee and MSC was requested to submit names of two proposed

members. It was suggested that the nominees be familiar with the mission

planning and constraints of the Apollo program. The first meeting was planned

for late July.

On July 29, MSC Director Robert R. Gilruth submitted the names of William A.

Lee and William E. Stoney, Jr. He noted that the same two individuals were being

nominated to serve as MSC members on the Apollo Site Selection Board. Gilruth

expressed a desire that the meetings of the two groups could be coordinated to

the extent that travel would be minimized.

Letter, Homer E. Newell, Associate Administrator for Space Science and

Applications, to MSC, Attn: Dr. Robert R. Gilruth, "Members of Ad Hoc

Surveyor/Orbiter Utilization Committee," June 22, 1965; letter, Gilruth to

Newell, "Members of Ad Hoc Surveyor/ Orbiter Utilization Committee," July 29,

1965.

June 23

In a memorandum concerning Configuration Control Panel and

Configuration Control Board actions, J. Thomas Markley, Chief of ASPO's Program

Control Division, pointed out that many proposals coming before the two groups

were not being adequately evaluated for program impact by the responsible

subsystem or technical area manager. He said, in part, "We must keep the number

of changes to a minimum and incorporate only those that are necessary to meet

program objectives. We are beyond the time when we can afford the luxury design

improvement changes, unless they can show substantial savings to the overall

program. . . ."

Memorandum, Markley to Distr., "CCB/CCP Actions," June 23, 1965.

June 23

The operational requirement for Block I and Block II CSM HE

orbital communications capability was investigated. ASPO requested that

appropriate contract direction and specification change notices be submitted

immediately to eliminate this capability from the Block II CSM and the

practicality of eliminating the HE orbital capability from the Block I CSM be

investigated.

Memorandum, William A. Lee, MSC, to Subsystem Manager, CSM Communications

Subsystem, "Requirement for Block I and Block II CSM HF Orbital Communications

Capability," June 23, 1965.

June 24-July 1

Dalmo-Victor submitted to MSC a report on modifications

necessary to extend to lunar distances the operating range of the CSM's

high-gain antenna. The Instrumentation and Electronic Systems Division was

reviewing the report.

MSC, "ASPO Weekly Management Report, June 24-July 1, 1965."

June 24-July 1

MSC completed a cursory analysis of LEM landing gear

load-stroke requirements at touchdown velocities of 2.43 m (8 ft) per sec

vertical and 1.22 m (4 ft) per sec horizontal. This study was conducted to

determine the lowest crush loads at 8-4 velocity to which the gear could be

designed and still meet its landing performance requirements.

Ibid.; memorandum, William G. McMullen, MSC, to Manager, ASPO,

"Elimination of TM-5 vehicle from the LEM Landing Gear Subsystem Test Program,"

July 7, 1965.

June 25

NASA announced the appointment of Col. C. H. Bolender as Mission

Director for the first and second Apollo/Saturn IB flights. Bolender was

assigned to the Mission Operations Organization in the Office of Manned Space

Flight, NASA.

NASA News Release 65-211.

June 25

MSC approved North American's concept for thermal control of the

valves in the CM's reaction control system (essential for long-duration

missions). The crew could electrically heat the valves for about ten minutes

before CSM separation and before the system was pressurized, thereby

forestalling possible freezing of the oxidizer when it contacted the valve.

Letter, C. L. Taylor, MSC, to NAA, Space and Information Systems Division,

Attn: J. C. Cozad, "Contract NAS 9-150, Effects of Spacecraft Venting Systems on

RCS Propellant Requirements, Determination of," June 23, 1965.

June 25

Harry L. Reynolds, Assistant Manager of ASPO, said it was

"becoming increasingly clear that we are going to have a difficult job keeping

the LEM weight below the control weight." He said the Grumman effort was not

adequate and suggested that R. Bullard of MSC be given LEM weight control as a

full-time responsibility.

Memorandum, Reynolds to Chief, Systems Engineering Division, "LEM Weight

Control," June 25, 1965.

June 25

ASPO informed Grumman, NAA, AC Spark Plug, and MIT that

effective June 21, 1965, General Electric Company, Apollo Support Department,

Daytona Beach, Fla., had assumed responsibility for the preparation and conduct

of all automatic checkout equipment (ACE) training for NASA and its contractors.

To satisfy conditions of its contract, General Electric would:

- Survey NASA and contractor ACE training requirements and prepare for ASPO

endorsement a standard set of lesson plans (course outlines) for three

distinct ACE training courses -

- for ACE operators and operational checkout procedures writers,

- for personnel who had site assignments but were not operators, and

- for all other individuals who did not satisfy the aforementioned

assignment considerations.

- Issue with ASPO approval a lesson plan for each ACE training course. These

plans would be considered baseline documents and deviations would not be

permitted without prior approval from ASPO.

- Prepare one study guide which would contain common reference information

for all three ACE training courses.

- Issue coordinated ACE training schedules approved by ASPO.

- Distribute monthly status reports to each participating organization.

'This report would contain a training schedule for the next three months as

well as a discussion of achievements. To control established plans and

implement changes, the coordinator for each participating organization would

be responsible for determining local training requirements and coordinating

those needs with other contractors or NASA elements who desired training at

that facility.

- Issue a citation which would acknowledge satisfactory course completion to

those qualifying students.

Purpose of selection of a single ACE

training contractor and establishment of a standard set of courses was to

provide participating organizations a sufficient amount of training and a

universal understanding of ACE.

Letters, R. Wayne Young, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, ACE Training," June 25, 1965; M. E. Dell, MSC, to AC Spark Plug, Attn:

Hugh Brady, "Contract NAS 9-497, ACE Training," June 28, 1965; M. E. Dell, MSC,

to MIT, Attn: M. B. Trageser, "Contract NAS 9-4065, ACE Training," June 28,

1965; J. B. Alldredge, MSC, to NAA, Space and Information Systems Division,

Attn: J. C. Cozad, "Contract NAS 9-150, ACE Training," June 29, 1965.

June 25

NASA announced negotiations with Douglas Aircraft Company for

nine additional S-IVB stages to be used as the third stage of the Saturn V

launch vehicle being developed at Marshall Space Flight Center. Work was to

include related spares and launch support services. The S-IVB contract,

presently valued at $312 million, would be increased by $150 million for the

additional work.

NASA News Release 65-209, "NASA to Negotiate with Douglas for more S-IVB

Stages," June 25, 1965; Space Business Daily, June 28, 1965, p.295.

June 25

MSC approved North American's proposed location of the antenna

for the radar transponder in the CSM, as well as the transponder's coverage.

This action followed a detailed review of the relative positions of the two

spacecraft during those mission phases when radar tracking of the LEM was

required.

Letter, R. Wayne Young, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, Radar Transponder Antenna Location on CSM," June 25, 1965.

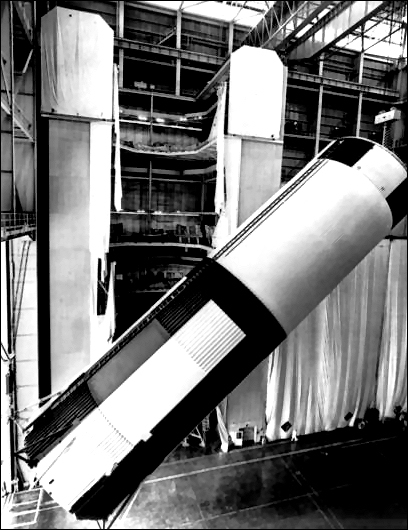

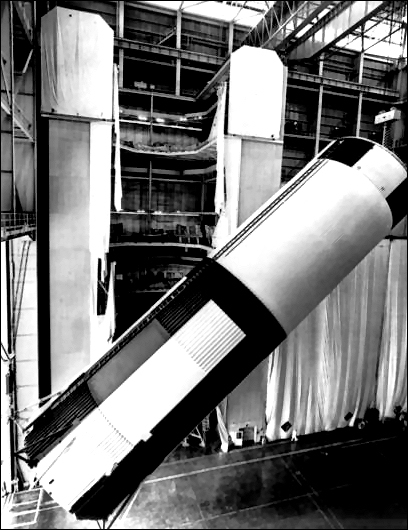

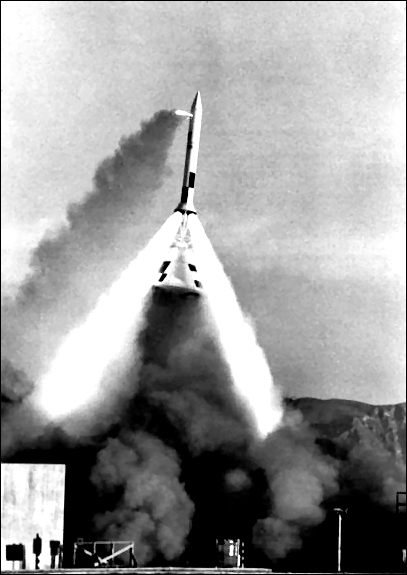

The first ground-test version of the Saturn V's first stage is shown

being removed from its vertical assembly tower at NASA's Michoud Operations

Facility June 27, 1965. The stage was 10 m (33 ft) in diameter and 42 m (138 ft)

tall.

June 28

Owen E. Maynard, Chief of the Systems Engineering Division,

vetoed a demand by the Flight Control Division for redundancy in the LEM's pulse

code modulation telemetry system. Two factors determined Maynard's action:

- cost and schedule impacts, and

- the resultant weight and power increases that redundancy would impose.

Also it would produce only a "marginal" increase in the total reliability of

the spacecraft.

Memorandum, Owen E. Maynard, MSC, to Chief, Flight

Control Division, "LEM PCM telemetry redundancy," June 28, 1965.

June 28

Systems Engineering Division chief, Owen E. Maynard, reported to

the Instrumentation and Electronic Systems Division (IESD) the results of a

study on a LEM communications problem (undertaken by his own group at IESD's

request). During phases of powered descent to certain landing sites (those in

excess of 20 degrees east or west longitude), the structure of the spacecraft

would block the steerable antenna's line of sight with the earth. Communications

with the ground would therefore be lost. Maynard concurred with IESD that the

problem could best be solved by rotating the LEM about its thrust axis.

Memorandum, Owen E. Maynard, MSC, to Chief, Instrumentation and Electronic

Systems Division, "Providing adequate earth coverage from the LEM S-band

steerable antenna during lunar descent and ascent," June 28, 1965.

June 28

John H. Disher, Director of the OMSF Apollo Test Office,

stressed two broad areas open to concern in the Apollo spacecraft heatshield

development program:

- structural integrity, and

- flight-test confirmation of the Block II design.

The structural

integrity question centered around the following problems: welding, ablative

material integrity, and impact strength.

MSC had planned to qualify the Block II heatshield by flight tests of

modified Block I spacecraft 017 and 020. Some of the Block II changes could not

be incorporated into modified Block I spacecraft in time to meet the current

schedule and limitations of facilities would not permit full evaluation of all

modifications by ground testing.

Disher suggested to Apollo Program Director Samuel C. Phillips that ASPO

Manager Joseph Shea be asked to present physical descriptions of the Block I and

Block II heatshields, and interim versions as applied to specific spacecraft, as

well as the test plan that would ensure adequacy of heatshields to meet mission

requirements. Memorandum, Disher to Phillips, "Apollo Spacecraft Heat Shield,"

June 28, 1965.

MSC directed North American to design the CM to store one integrated thermal

meteoroid garment (TMG), rather than merely the thermal covering alone. The

crewmen would carry the TMG into the LEM for use during extravehicular

operations.

Letter, J, B. Alldredge, MSC, to NAA, Space and Information Systems Division,

"Contract Change Authorization No. 371," June 29, 1965.

June 29

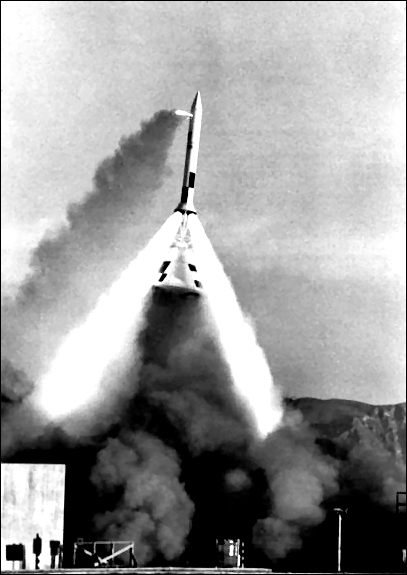

The launch of PA-2.

NASA launched Apollo mission PA-2, a test of the launch escape system (LES)

simulating a pad abort at WSMR. All test objectives were met. The escape rocket

lifted the spacecraft (boilerplate 23A) more than 1,524 m (5,000 ft) above the

pad. The earth landing system functioned normally, lowering the vehicle back to

earth. This flight was similar to the first pad abort test on November 7, 1963,

except for the addition of canards to the LES (to orient the spacecraft blunt

end forward after engine burnout) and a boost protective cover on the CM. PA-2

was the fifth of six scheduled flights to prove out the LES. [Mission objectives

in Appendix 5.]

Memorandum, George E. Mueller, NASA, to Administrator, "Apollo Spacecraft Pad

Abort Test, Mission PA-2, Post Launch Report No. 1," July 2, 1965; MSC,

"Postlaunch Report for Apollo Mission PA-2 (BP-23A)," July 29, 1965, pp. 1-1,

2-1, 3-1, and 10-1.

June 29

North American reported to MSC that no structural changes to the

spacecraft would be required for uprating the thrust of the Saturn IB's H-1

engine from 90,718 to 92,986 kg (200,000 to 205,000 lbs). Effects on the

performance of the launch escape vehicle would be negligible.

Letter, H. G. Osbon, NAA, to NASA MSC, Attn: C. L. Taylor, "Contract NAS

9-150, R&D for Project Apollo Spacecraft; Spacecraft Structural Impact of

Increase of H-1 Engine," June 29, 1965.

June 29

NASA formally announced the selection of six

scientist-astronauts for the Apollo program, chosen from a group nominated by

America's scientific community. Qualifications and recruiting procedures had

been worked out earlier by NASA and the National Academy of Sciences' Ad Hoc

Committee on Scientific Qualifications of Scientist-Astronauts. To be eligible,

candidates must have been born on or after August I, 1930; be citizens of the

United States; be no more than 1.83 m (6 ft) tall; and have an educational level

of a doctorate or the equivalent in experience. The six, only one of whom was on

active military service, were Owen K. Garriott, Edward G. Gibson, Duane E.

Graveline, Lt. Cdr. Joseph P. Kerwin (USN), Frank Curtis Michel, and Harrison

Schmitt.

Letter, Homer E. Newell, NASA, to Robert R. Gilruth, MSC, August 19, 1964,

with attachment, "Suggested Public Announcement of the Scientist-Astronaut

Program," August 19, 1964; letter, Newell to Harry H. Hess, NAS, August 19,

1964; NASA News Release 64-315, "NASA Reports Some 900 Persons Interested in

Scientist-Astronaut Program," December 16, 1964; MSC News Release 64-195,

December 16, 1964; MSC News Release 65-63, June 29, 1965.

June 30

Langley Research Center put into operation its 3.5 million Lunar

Landing Research Facility. The huge structure (76.2 m [250 ft] high and 121.9 m

[400 ft] long) would be used to explore techniques and to forecast various

problems of landing on the moon. The facility would enable a test vehicle to be

operated under one-sixth g conditions.

Astronautics and Aeronautics, 1965, p. 303; Michael David

Keller, Fifty Years of Flight Research: A Chronology of the Langley

Research Center, 1917-1966 (HHN-65), November 1966, p. 89.

June 30

In a memorandum to T. Tarbox, John Ryken, Bell Aerosystems

Company LLRV Project Manager, said he understood that Dean Grimm of MSC believed

that the LLRV was not configured to have the jet engine provide simulation of a

constant-lift rocket thrust in addition to providing the 5/6th g lift. Ryken

forwarded to Tarbox a copy of a report, "LLRV Automatic Control System Service

and Maintenance Manual," plus notes on the system in the hope that these would

help him and NASA personnel better understand the system. He also included

suggestions about reducing aerodynamic moments which Grimm felt might interfere

with LEM simulation.

Interoffice Memo, Bell Aerosystems Company, J. Ryken, Bell, to T. Tarbox,

Bell, "LLRV," June 30, 1965.